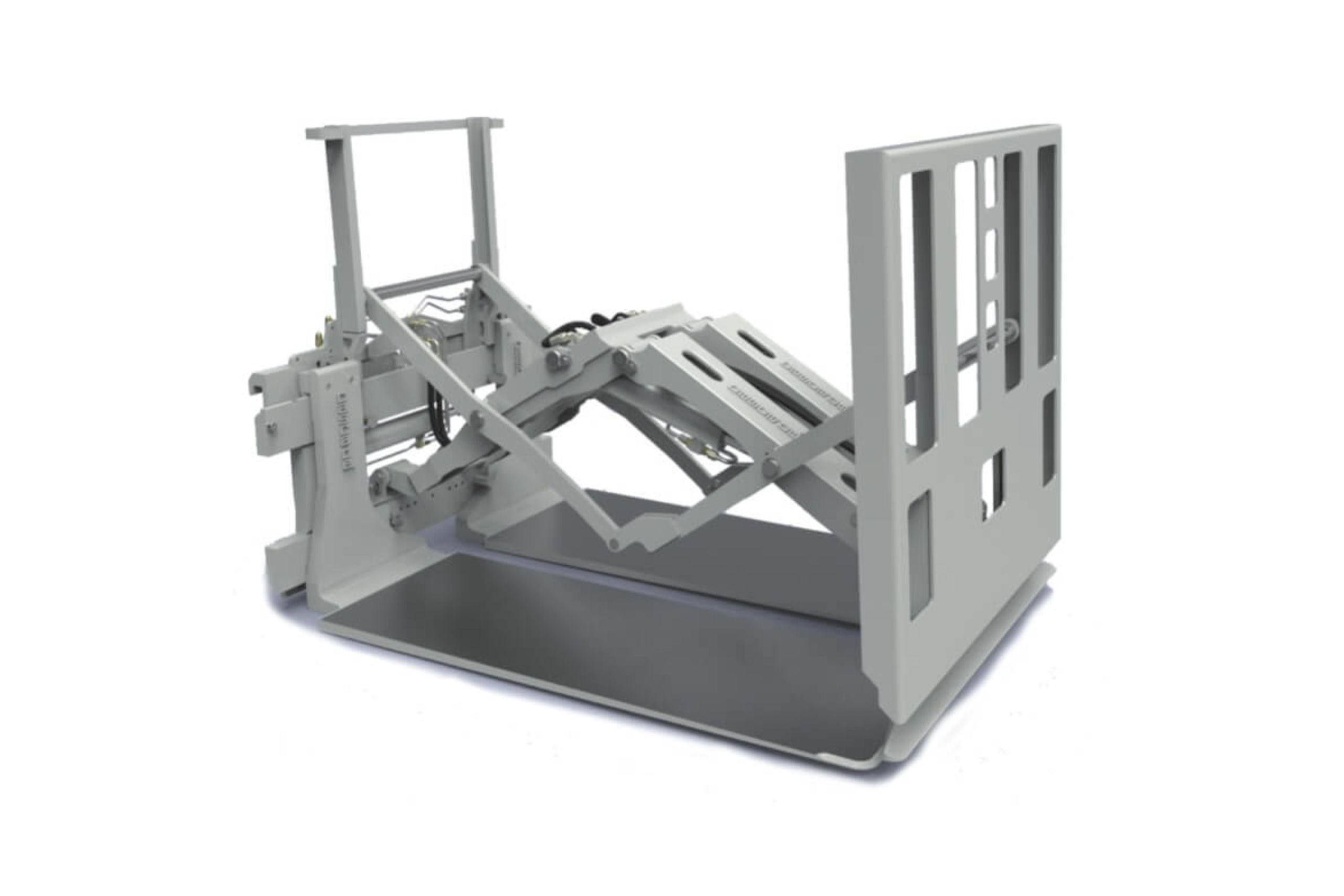

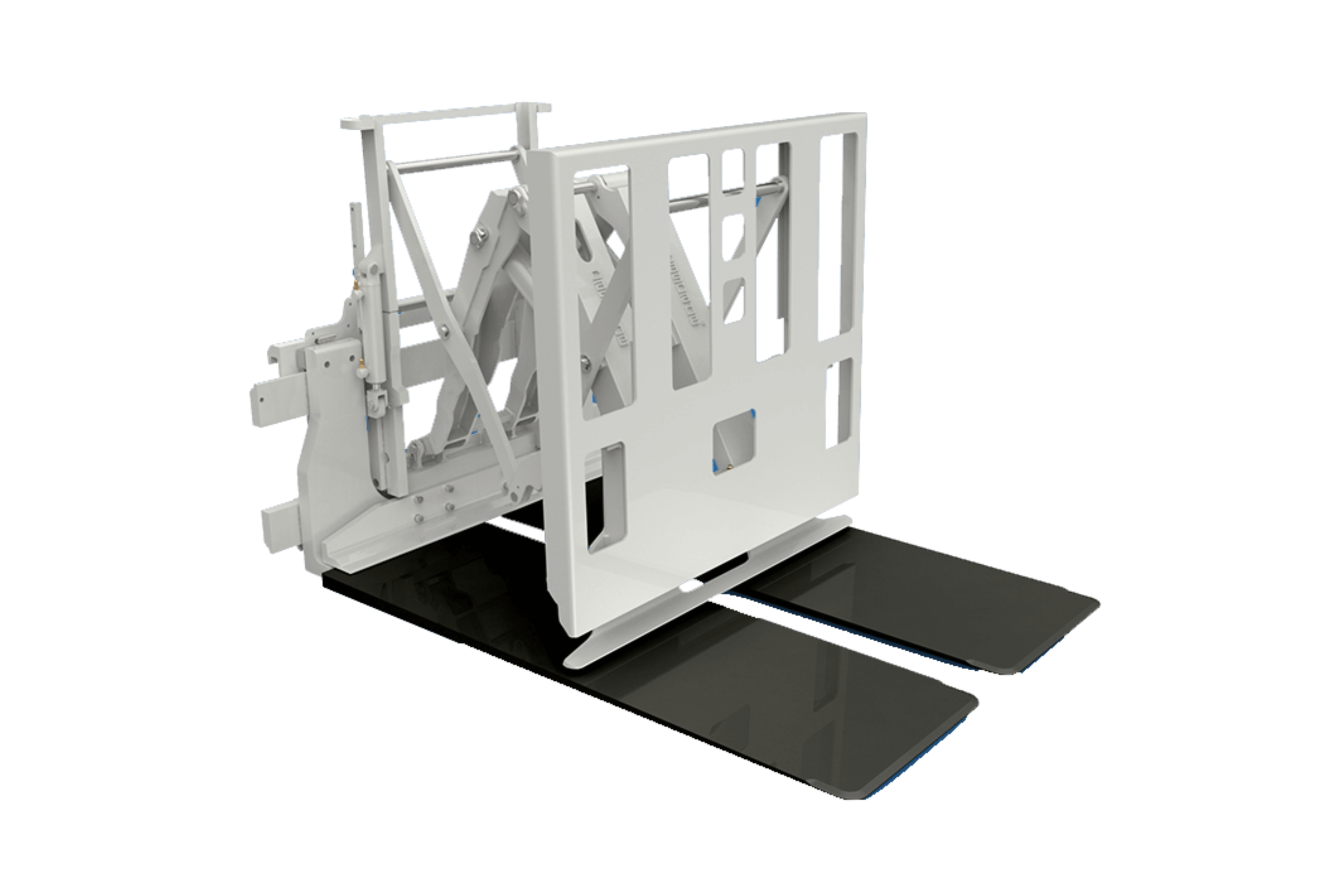

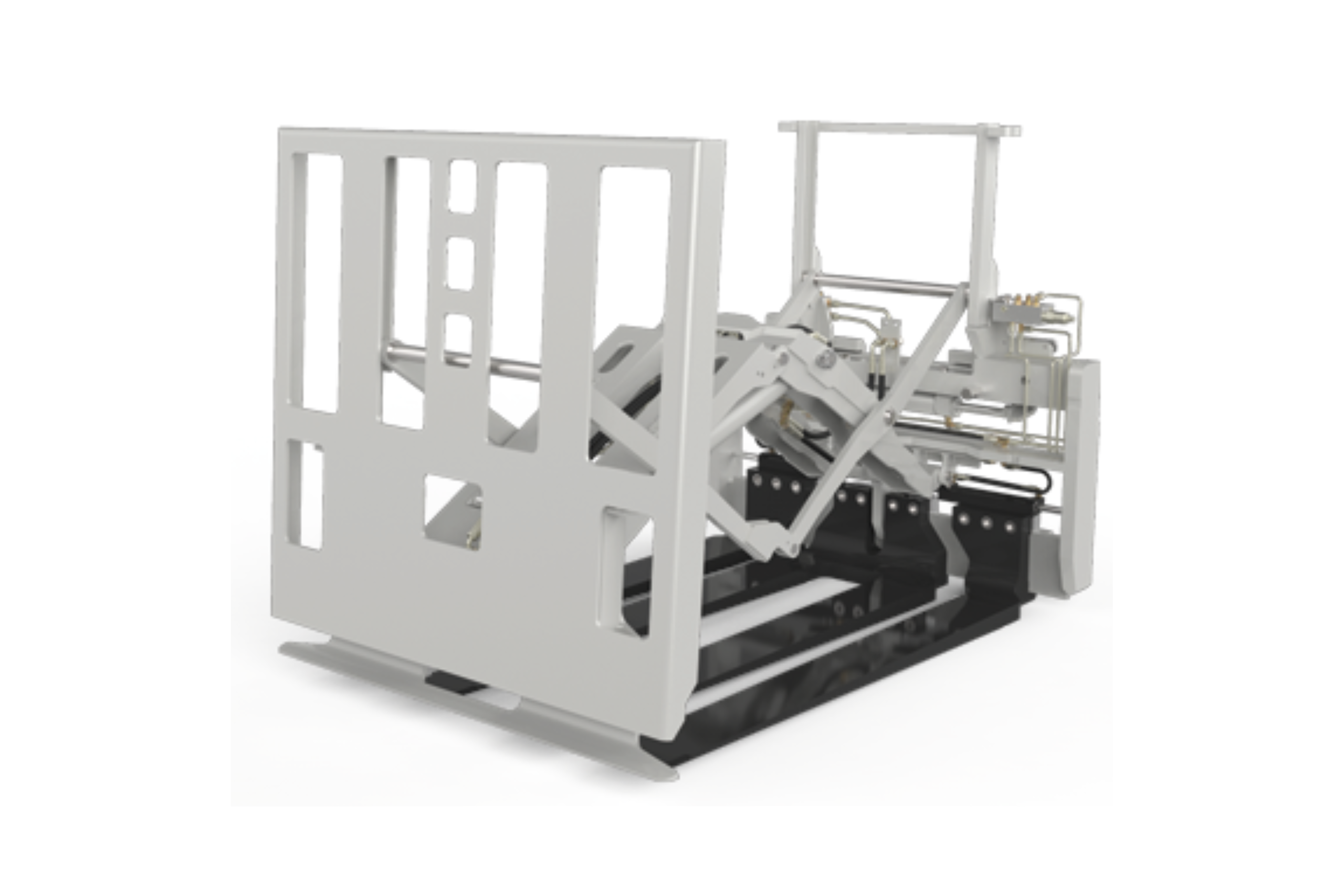

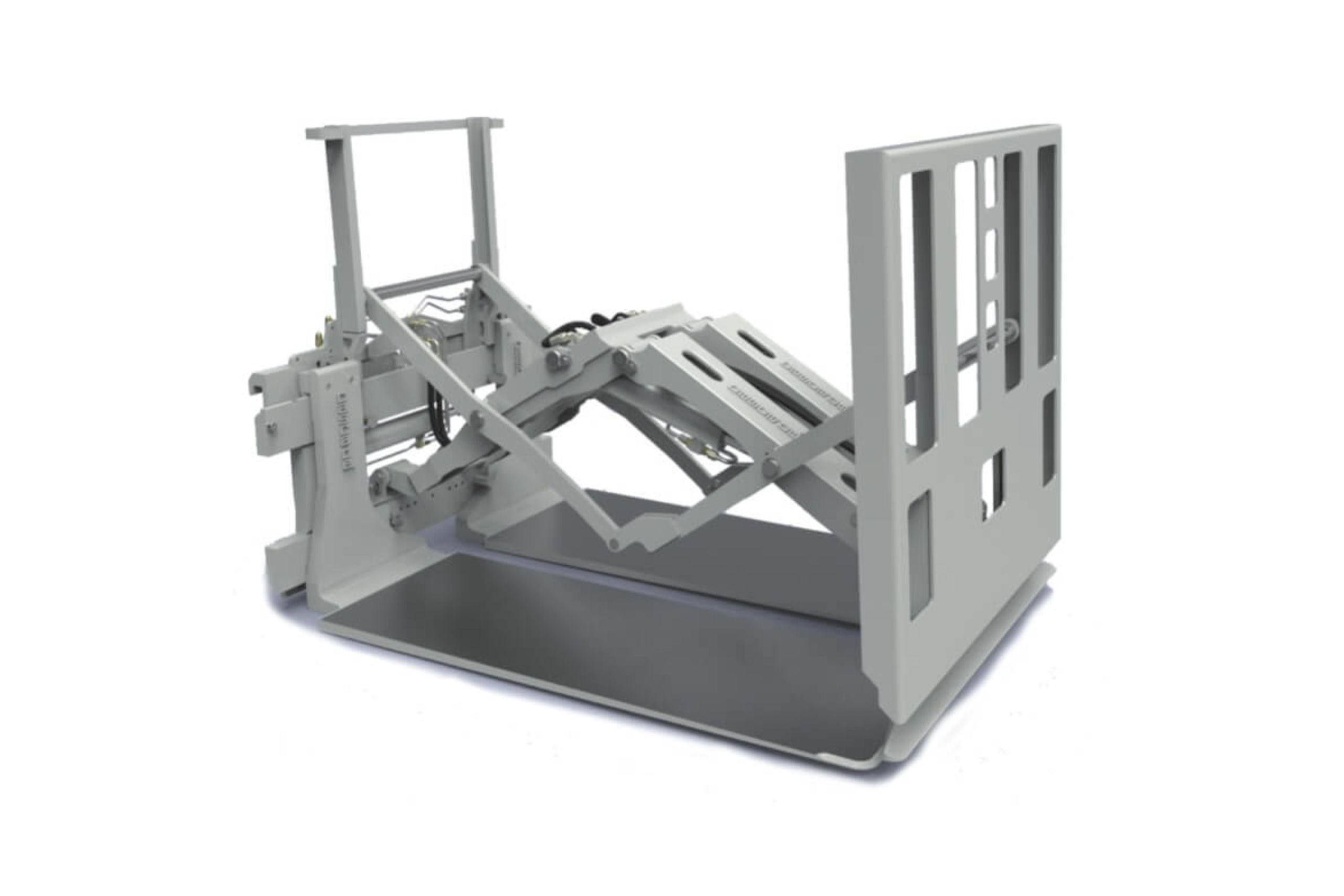

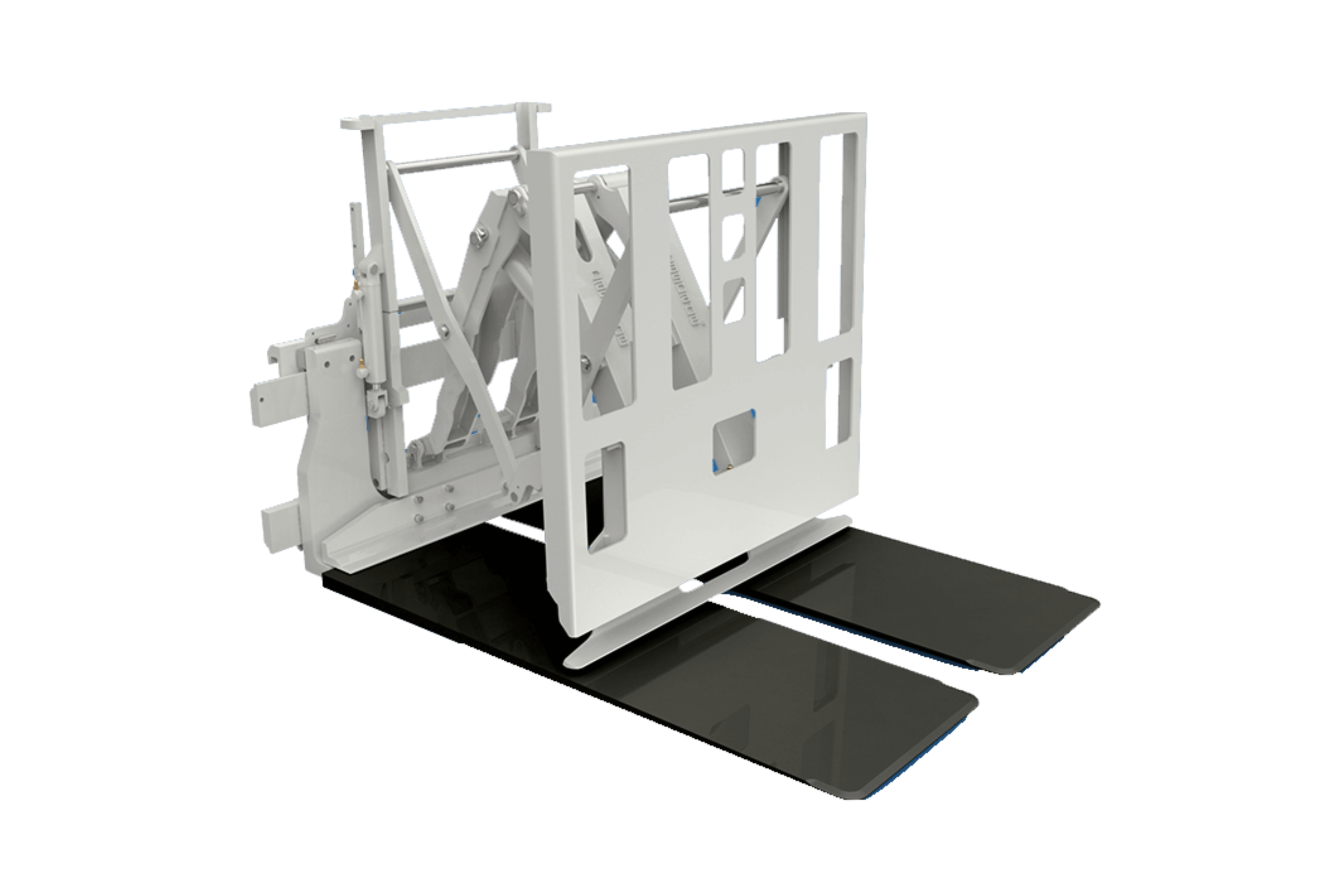

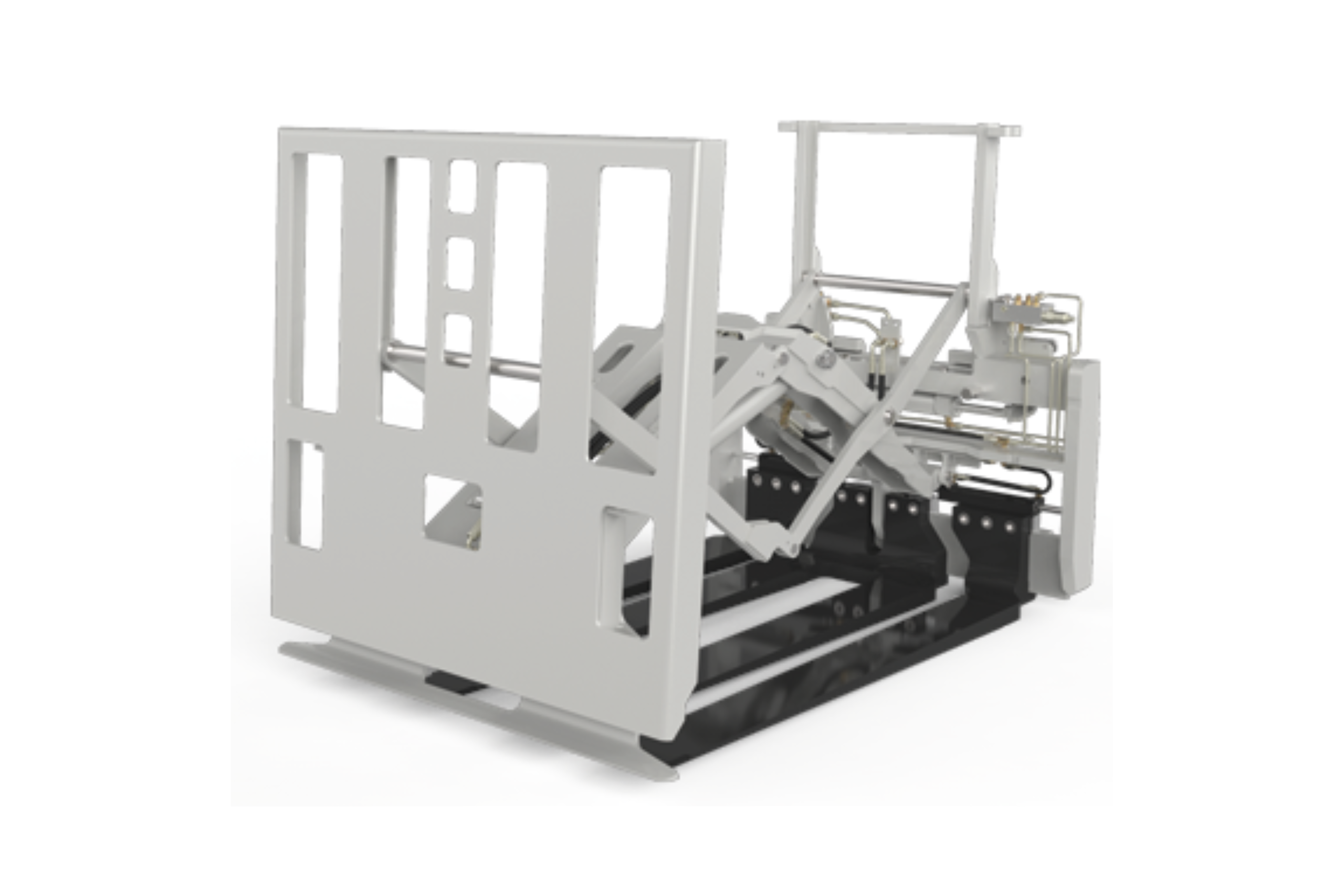

QFM (Quick Fork Mount) Push/Pulls are ideal for applications requiring quick and convenient removal and installation of a push/pull attachment. The rugged Cascade QFM can be installed or removed in less than one minute and does not require removal of the lift truck forks. Ideal for applications requiring an attachment for slipsheets on an intermittent or irregular basis

| Product Features | Description |

|---|---|

| Quick-Fork Mounting | Can be installed or removed in under one minute without removing the truck forks. |

| Chamfered Platen Corners | Prevents tears in slipsheets during handling. |

| Gripper Jaw Design | Protects tabs of slipsheets from damage. |

| 4° Tilting Faceplate | Helps align the slipsheet for easier engagement. |

| Frame Mounted Between Forks | Designed with 20.5″ spacing to minimize “lost load” (effective thickness). |

| High-Visibility Design | The pantograph, gripper jaw, and faceplate are made for operator visibility. |

| Rigid Pantograph Mechanism | High strength and rigid design for durability. |

| Abrasion-Resistant Steel Platens | To resist wear in repeated use. |

| Protected Hydraulics | Cylinders, valves, and hydraulic lines are enclosed within the arms for protection. |

| Parameter | Range / Example Values | Notes / Conditions |

|---|---|---|

| Capacity | 3,500 lb to 4,500 lb (≈ 1,600 to 2,070 kg) | Typical for QFM Push/Pull in its product class |

| Hydraulic Pressure (Max) | 2,300 psi (160 bar) | The maximum system pressure allowed |

| Hydraulic Flow (Min / Recommended / Max) | 4 GPM minimum, 7 GPM nominal, 10 GPM maximum (≈ 15 / 26 / 38 L/min) | Flow below minimum reduces speed; flow above max can overheat the system |

| Mounting Class | Class II (with also Class III options) | The attachment mounts on standard fork carriage classes |

| Platen Size Options | 15″ × 48″ and 18″ × 48″ are standard examples | Variation in platen width and length possible |

| Attachment Weight | ~ 640 lb to ~ 965 lb depending on model (for example QFM variants) | Heavier models have larger or more robust components |

| Effective Thickness (ET) | Example: ~ 6.5″ in some II-class units | The “thickness” the push/pull adds to the forklift carriage |

| Horizontal / Vertical Center of Gravity | Example: HCG ~ 9.7″, VCG ~ 12.1″ for a 35E variant with 18×48 platen | Varies by configuration |

| Platen Spacing / Adjustability | Options for spacing – e.g. 4″ or 10″ spacing between platens | To suit load widths |

| Mounting / Fork Requirements | Forks must be spaced 20.5″ – 25.5″ (inside to inside); fork thickness up to 1.8″ with spacers | For correct fit and structural support |

| Options | Description |

|---|---|

| Quick-Change Hydraulic Couplers | Enables fast, tool-free connection/disconnection of hydraulic lines during attachment swaps. |

| Special Faceplate Heights / Widths | Custom faceplate dimensions to better suit particular load sizes or slip-sheet widths. |

| Faceplate Stop Group | A mechanism to limit or stop the faceplate’s travel (extension/retraction) at a set point. |

| Truck-Mounted Solenoid Adaption Group | Allows solenoid control units to be mounted on the forklift (truck) side for better integration and control. |

| Class III Mounting | In addition to the standard Class II mounting, this option allows QFM to be used on Class III carriages. |

| Various Platen Sizes / Spacing | Alternate platen dimensions and spacing (e.g. wider, narrower, longer versions) to match different slip-sheet or load sizes. |

| Extended Push / Stroke Lengths | Increased stroke length so the faceplate can push deeper into loads (for deeper pallets or stacks). |

| Special Load Backrest for Truck Carriage | A backrest that provides support to the load and integrates with the forklift’s carriage to ensure load stability. |

QFM (Quick Fork Mount) Push/Pulls are ideal for applications requiring quick and convenient removal and installation of a push/pull attachment. The rugged Cascade QFM can be installed or removed in less than one minute and does not require removal of the lift truck forks. Ideal for applications requiring an attachment for slipsheets on an intermittent or irregular basis

| Product Features | Description |

|---|---|

| Quick-Fork Mounting | Can be installed or removed in under one minute without removing the truck forks. |

| Chamfered Platen Corners | Prevents tears in slipsheets during handling. |

| Gripper Jaw Design | Protects tabs of slipsheets from damage. |

| 4° Tilting Faceplate | Helps align the slipsheet for easier engagement. |

| Frame Mounted Between Forks | Designed with 20.5″ spacing to minimize “lost load” (effective thickness). |

| High-Visibility Design | The pantograph, gripper jaw, and faceplate are made for operator visibility. |

| Rigid Pantograph Mechanism | High strength and rigid design for durability. |

| Abrasion-Resistant Steel Platens | To resist wear in repeated use. |

| Protected Hydraulics | Cylinders, valves, and hydraulic lines are enclosed within the arms for protection. |

| Parameter | Range / Example Values | Notes / Conditions |

|---|---|---|

| Capacity | 3,500 lb to 4,500 lb (≈ 1,600 to 2,070 kg) | Typical for QFM Push/Pull in its product class |

| Hydraulic Pressure (Max) | 2,300 psi (160 bar) | The maximum system pressure allowed |

| Hydraulic Flow (Min / Recommended / Max) | 4 GPM minimum, 7 GPM nominal, 10 GPM maximum (≈ 15 / 26 / 38 L/min) | Flow below minimum reduces speed; flow above max can overheat the system |

| Mounting Class | Class II (with also Class III options) | The attachment mounts on standard fork carriage classes |

| Platen Size Options | 15″ × 48″ and 18″ × 48″ are standard examples | Variation in platen width and length possible |

| Attachment Weight | ~ 640 lb to ~ 965 lb depending on model (for example QFM variants) | Heavier models have larger or more robust components |

| Effective Thickness (ET) | Example: ~ 6.5″ in some II-class units | The “thickness” the push/pull adds to the forklift carriage |

| Horizontal / Vertical Center of Gravity | Example: HCG ~ 9.7″, VCG ~ 12.1″ for a 35E variant with 18×48 platen | Varies by configuration |

| Platen Spacing / Adjustability | Options for spacing – e.g. 4″ or 10″ spacing between platens | To suit load widths |

| Mounting / Fork Requirements | Forks must be spaced 20.5″ – 25.5″ (inside to inside); fork thickness up to 1.8″ with spacers | For correct fit and structural support |

| Options | Description |

|---|---|

| Quick-Change Hydraulic Couplers | Enables fast, tool-free connection/disconnection of hydraulic lines during attachment swaps. |

| Special Faceplate Heights / Widths | Custom faceplate dimensions to better suit particular load sizes or slip-sheet widths. |

| Faceplate Stop Group | A mechanism to limit or stop the faceplate’s travel (extension/retraction) at a set point. |

| Truck-Mounted Solenoid Adaption Group | Allows solenoid control units to be mounted on the forklift (truck) side for better integration and control. |

| Class III Mounting | In addition to the standard Class II mounting, this option allows QFM to be used on Class III carriages. |

| Various Platen Sizes / Spacing | Alternate platen dimensions and spacing (e.g. wider, narrower, longer versions) to match different slip-sheet or load sizes. |

| Extended Push / Stroke Lengths | Increased stroke length so the faceplate can push deeper into loads (for deeper pallets or stacks). |

| Special Load Backrest for Truck Carriage | A backrest that provides support to the load and integrates with the forklift’s carriage to ensure load stability. |

Whether it’s about forklifts, parts, or services, we’ve got you covered. Our team is ready to help you find the right solution. Just let us know what you need.

1511 Railroad Street Corona, CA 92880

sales@scielifts.com

Phone : (951) 735-2905

By submitting this form, you agree to receive marketing emails from SCIE Lifts. You can unsubscribe at any time using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact