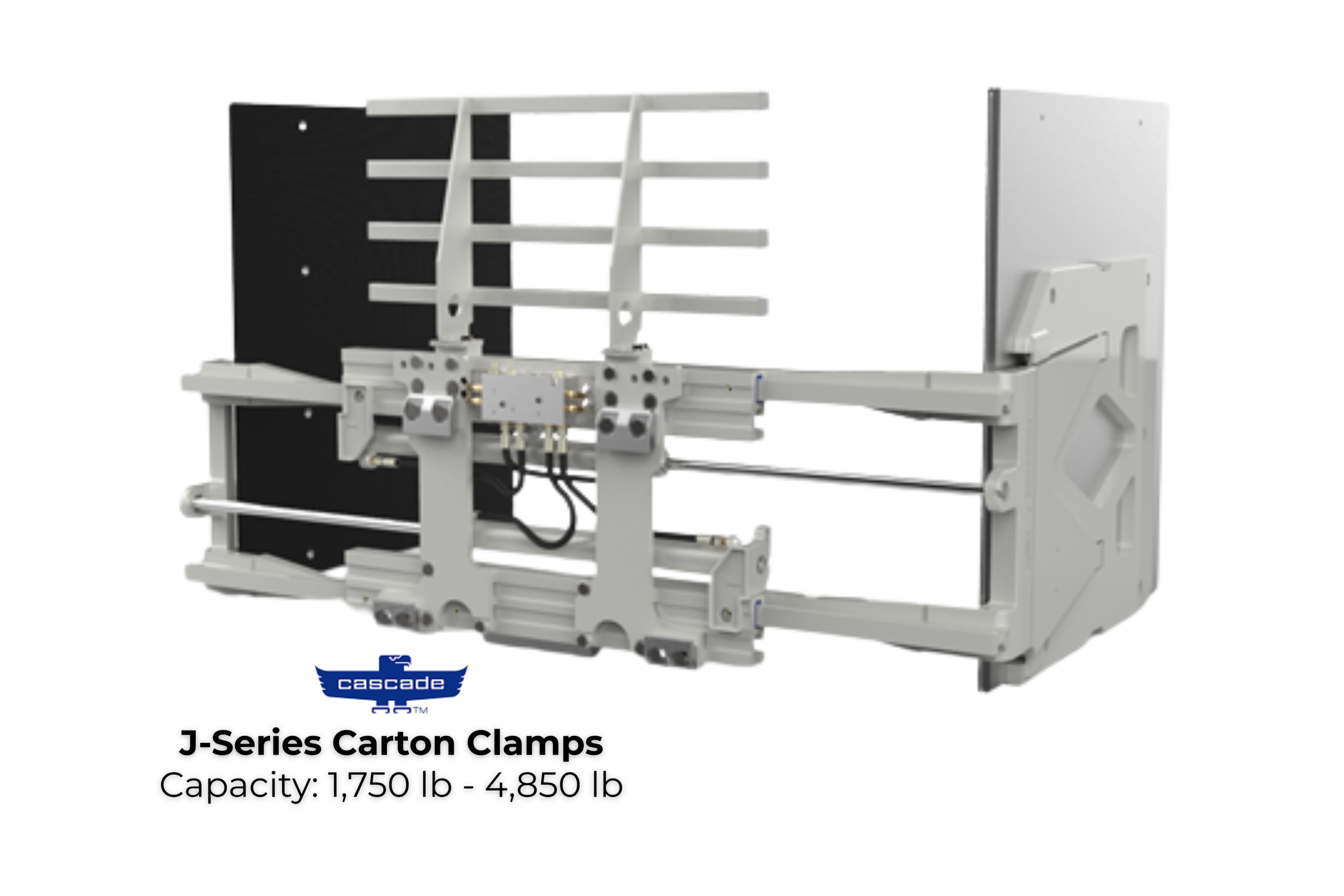

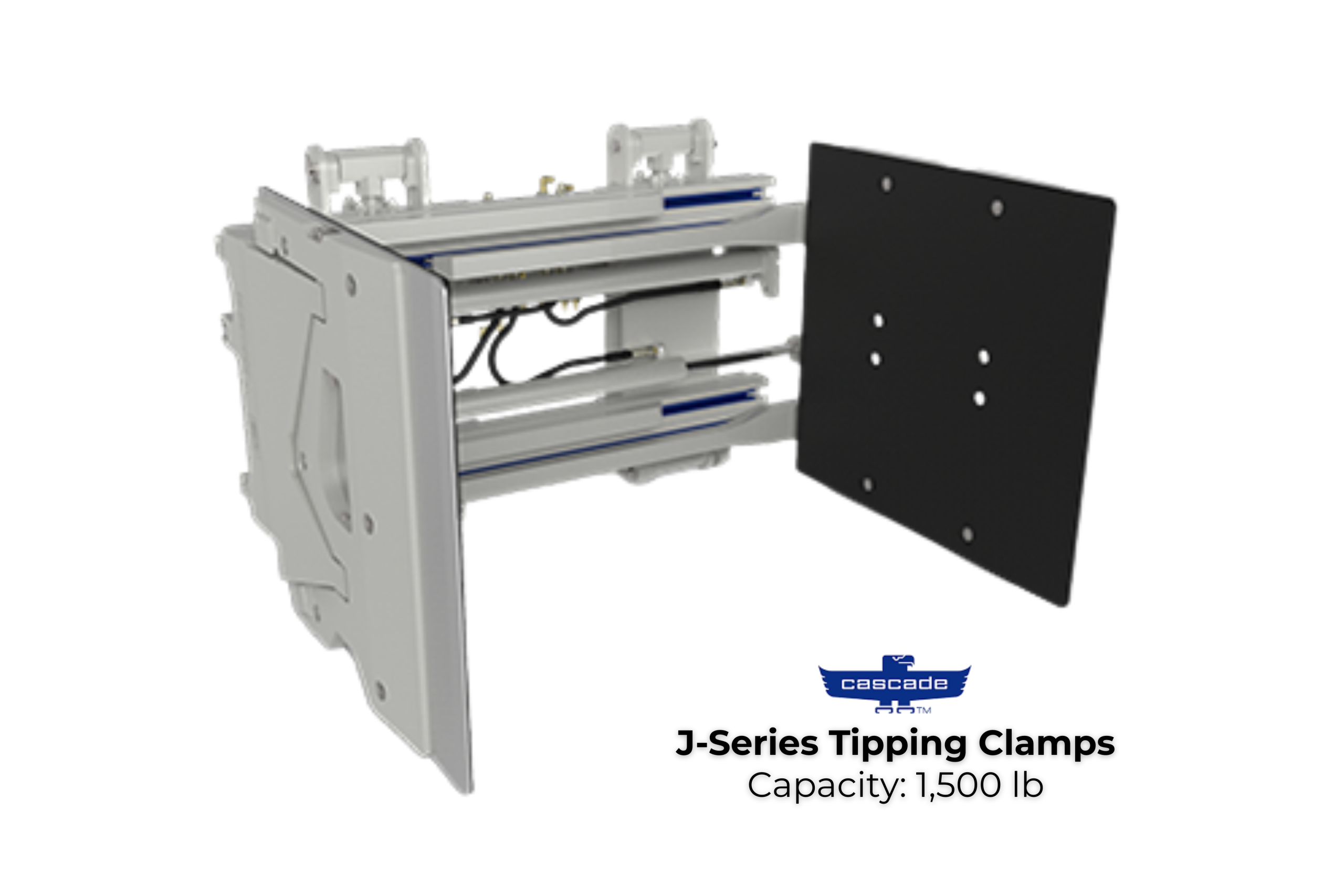

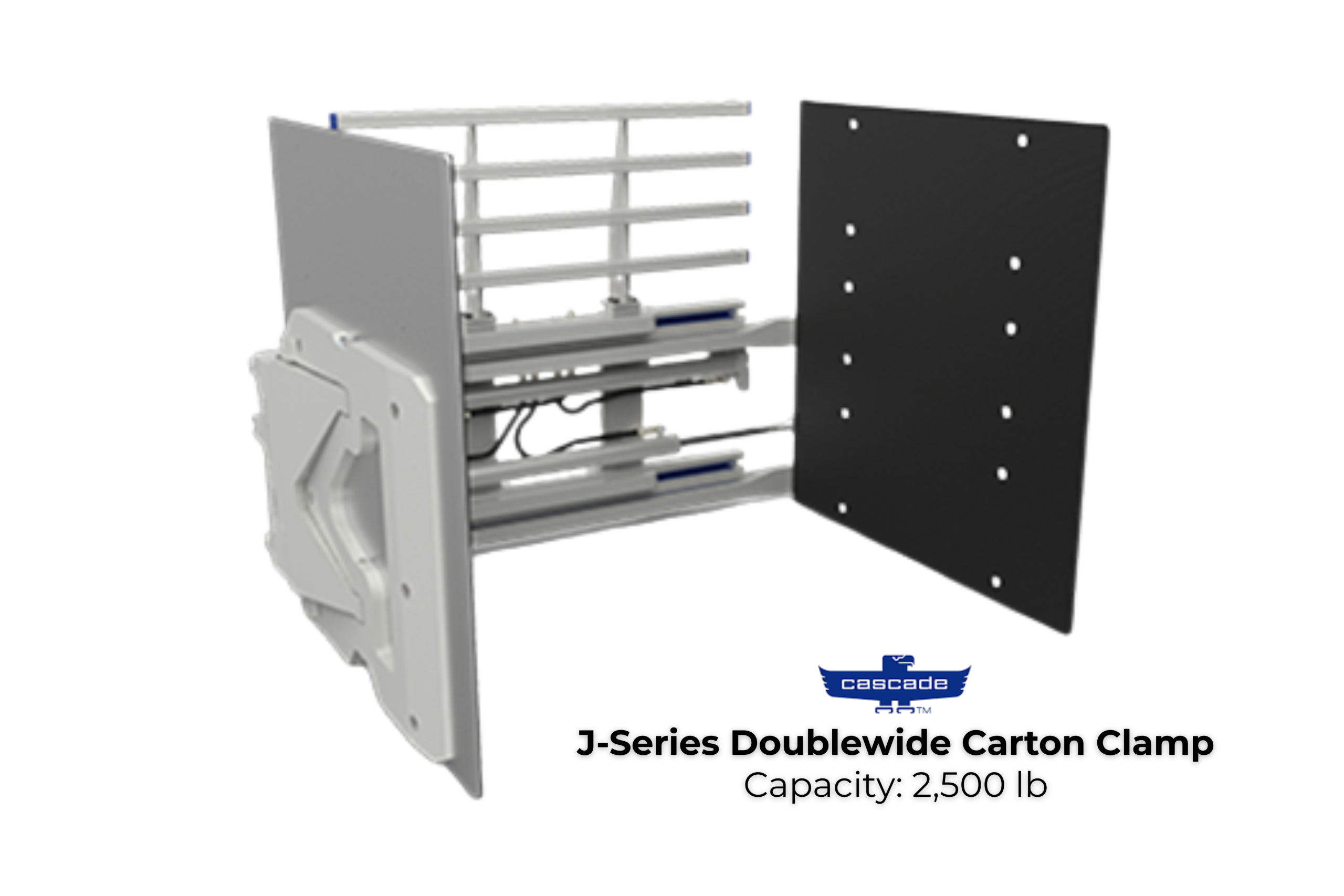

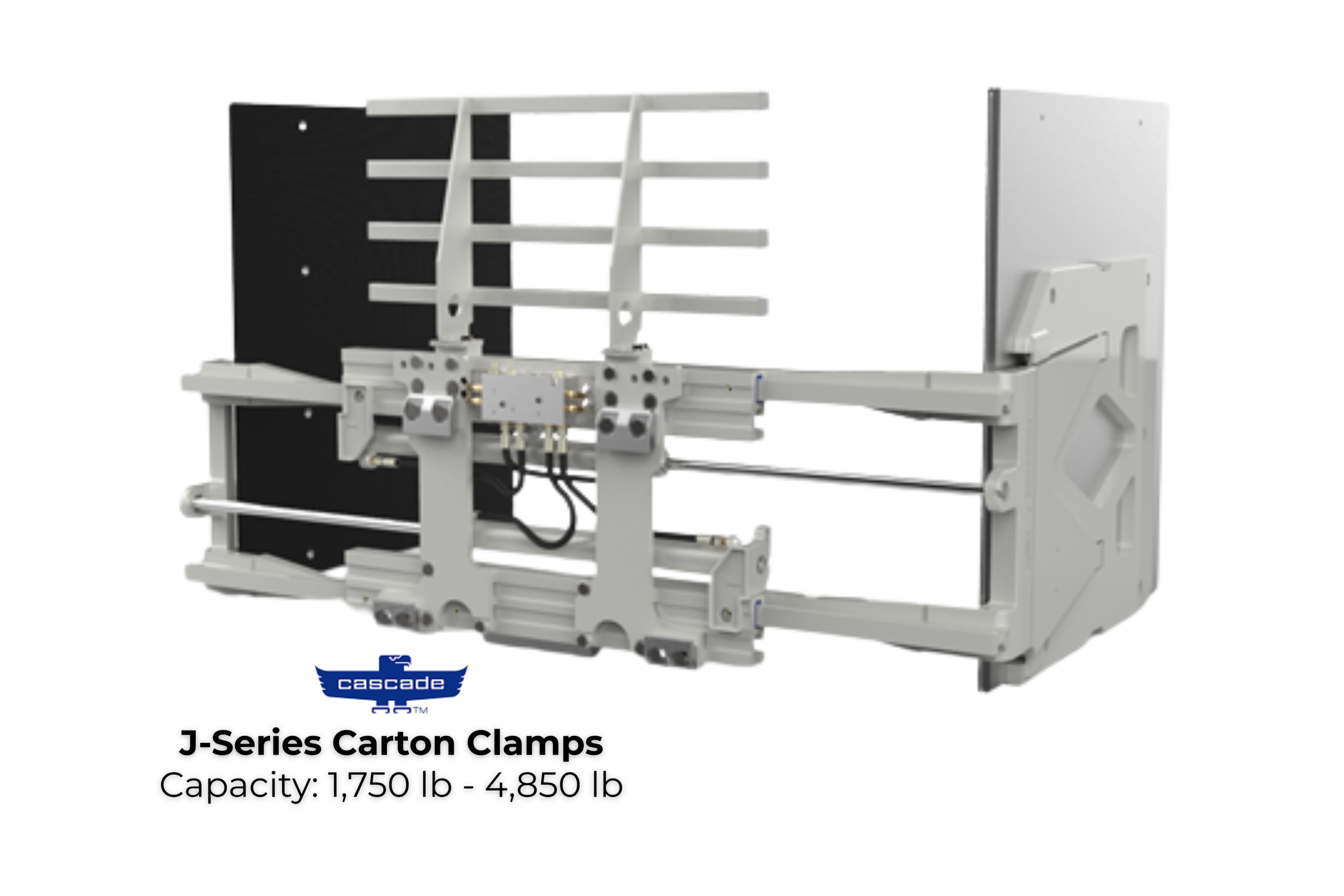

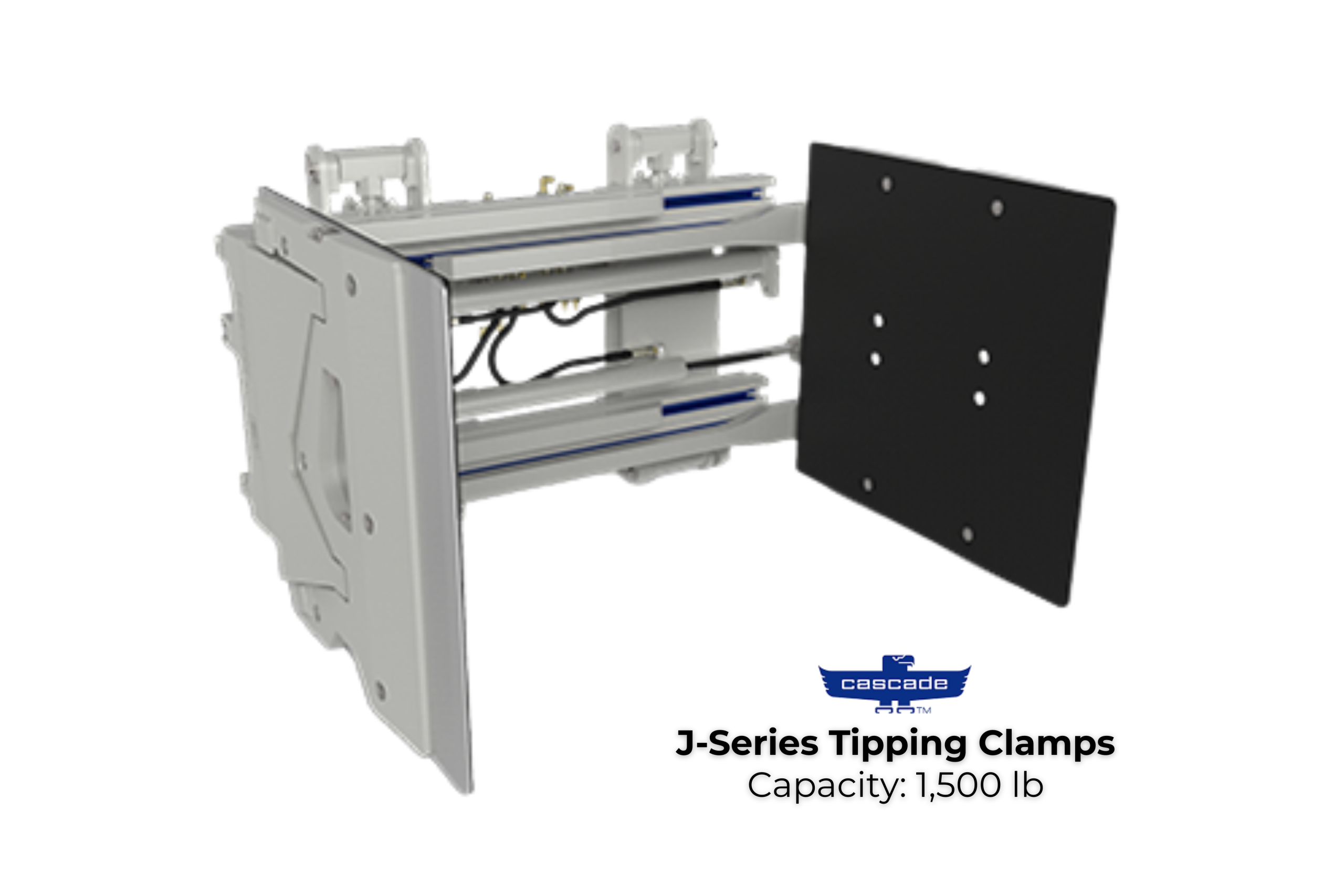

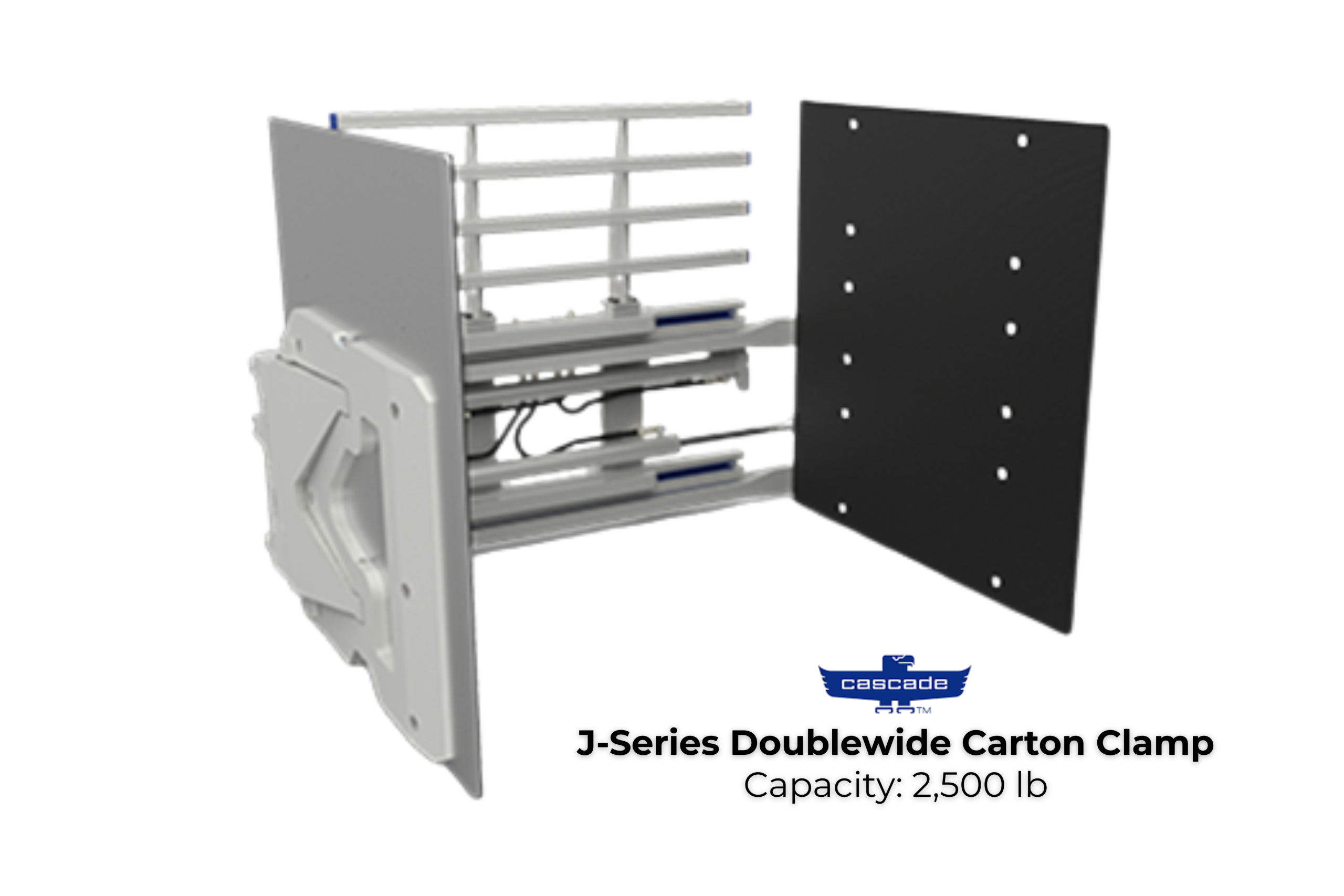

Whether you’re handling consumer paper products, appliances, consumer electronics, wine packaged foods (canned or boxed), chemicals or plastics, Cascade carton clamps offer a solution. They’re durable enough for the toughest conditions, versatile and easy to service.

Each Cascade carton clamp is designed to do a particular job, and do it well. For improved reliability, reduced product damage, reduced maintenance and ease of operation, think Cascade. The J-Series offers several models to fit your needs no matter your industry.

| Product Features | Description |

|---|---|

| Reversible Rubber Faced Contact Pad | Aluminum pad with rubber face can be reversed for extended wear life. |

| Durable Seals | Ensure long-lasting hydraulic performance and reduced maintenance. |

| UHMW Full-Length Bearings | Provide smooth movement and reduce wear on sliding components. |

| True Centering Key | Ensures precise alignment and stable clamping action. |

| Clamp, Sideshift & Open Relief Valve | Protects the system by regulating pressure during operation. |

| Industry-Leading Visibility | Frame design provides superior sight lines for safer, more accurate handling. |

| Efficient Hydraulic System | Minimizes energy use while maintaining maximum clamp performance. |

| Clamp & Backhand Protection | Built-in safeguards protect clamp arms and backhand surfaces during operation. |

| Flow Divider for Equal Arm Movement | Ensures synchronized and balanced clamping pressure on both arms. |

| Top-Mounted Hydraulic Cartridges & Test Port | Allows easier inspection, maintenance, and performance adjustments. |

| Sideshift Circuit Relief | Controls hydraulic pressure to optimize sideshift speed and safety. |

| High Strength Steel Frame & Castings | Provides durability, rigidity, and a long service life under heavy use. |

| Thin Arm Profile | Allows access in tight stacking situations without damaging loads. |

| Rubber-Faced Aluminum Contact Pads | Provides secure grip on loads while protecting surfaces from damage. |

| Two Pressure Offerings | Flexibility to match clamp pressure with the hydraulic system of the forklift. |

| Parameter | Description |

|---|---|

| Capacity | 1,750 lb to 4,850 lb (varies by series and model) |

| Arm / Contact Pad | Rubber-faced aluminum contact pads (standard) |

| Frame / Arm Design | Thin arm profiles for tight stacking; pivoting arms and stabilizers for force distribution |

| Hydraulic / Performance | Regenerative valve option available to increase clamp speed when truck hydraulic flow is limited |

| Mounting / Options | Quick-disconnect mounting, various pad sizes, articulating pads, tilt control, and custom opening ranges |

| Class / Variants | Available in J-Series, White Goods (WG), Razorback, D-Series, and other specialized models |

| Options | Description |

|---|---|

| Custom Opening Ranges & Frame Widths | Tailor the clamp to different carton sizes and warehouse layouts. |

| Custom Arm Lengths, Heights & Pad Surfaces | Adjust arm dimensions or change pad surfaces to match specific load requirements. |

| Various Contact Pad Sizes & Surfaces | Use pads with different shapes or materials to protect product surfaces or improve grip. |

| Articulating Pads | Pads that can adjust angle or position to match load geometry for full contact. |

| Quick-Disconnect Mounting | Enables faster removal or swapping of the attachment. |

| Frame Bumper / Protection | Added protection on the clamp frame to guard against impacts or abrasive loads. |

| Tilt Control | Ability to tilt or angle the clamp slightly for better load engagement. |

| Load Cushion | Cushioned contact to reduce impact and protect delicate cartons. |

| Independent Arm Control | Each arm can move independently for precise positioning in tight or asymmetric loads. |

| Regenerative Valve | Improves arm speed on trucks with limited hydraulic flow by recovering hydraulic energy. |

| External Sideshift | Allows the entire clamp body to shift sideways for easier load alignment. |

| Alternate Valve Configurations | Options for left-hand or right-hand third / fourth function hydraulic setups. |

| Application-Specific Customization | Tailored design changes to match industry or product needs. |

Whether you’re handling consumer paper products, appliances, consumer electronics, wine packaged foods (canned or boxed), chemicals or plastics, Cascade carton clamps offer a solution. They’re durable enough for the toughest conditions, versatile and easy to service.

Each Cascade carton clamp is designed to do a particular job, and do it well. For improved reliability, reduced product damage, reduced maintenance and ease of operation, think Cascade. The J-Series offers several models to fit your needs no matter your industry.

| Product Features | Description |

|---|---|

| Reversible Rubber Faced Contact Pad | Aluminum pad with rubber face can be reversed for extended wear life. |

| Durable Seals | Ensure long-lasting hydraulic performance and reduced maintenance. |

| UHMW Full-Length Bearings | Provide smooth movement and reduce wear on sliding components. |

| True Centering Key | Ensures precise alignment and stable clamping action. |

| Clamp, Sideshift & Open Relief Valve | Protects the system by regulating pressure during operation. |

| Industry-Leading Visibility | Frame design provides superior sight lines for safer, more accurate handling. |

| Efficient Hydraulic System | Minimizes energy use while maintaining maximum clamp performance. |

| Clamp & Backhand Protection | Built-in safeguards protect clamp arms and backhand surfaces during operation. |

| Flow Divider for Equal Arm Movement | Ensures synchronized and balanced clamping pressure on both arms. |

| Top-Mounted Hydraulic Cartridges & Test Port | Allows easier inspection, maintenance, and performance adjustments. |

| Sideshift Circuit Relief | Controls hydraulic pressure to optimize sideshift speed and safety. |

| High Strength Steel Frame & Castings | Provides durability, rigidity, and a long service life under heavy use. |

| Thin Arm Profile | Allows access in tight stacking situations without damaging loads. |

| Rubber-Faced Aluminum Contact Pads | Provides secure grip on loads while protecting surfaces from damage. |

| Two Pressure Offerings | Flexibility to match clamp pressure with the hydraulic system of the forklift. |

| Parameter | Description |

|---|---|

| Capacity | 1,750 lb to 4,850 lb (varies by series and model) |

| Arm / Contact Pad | Rubber-faced aluminum contact pads (standard) |

| Frame / Arm Design | Thin arm profiles for tight stacking; pivoting arms and stabilizers for force distribution |

| Hydraulic / Performance | Regenerative valve option available to increase clamp speed when truck hydraulic flow is limited |

| Mounting / Options | Quick-disconnect mounting, various pad sizes, articulating pads, tilt control, and custom opening ranges |

| Class / Variants | Available in J-Series, White Goods (WG), Razorback, D-Series, and other specialized models |

| Options | Description |

|---|---|

| Custom Opening Ranges & Frame Widths | Tailor the clamp to different carton sizes and warehouse layouts. |

| Custom Arm Lengths, Heights & Pad Surfaces | Adjust arm dimensions or change pad surfaces to match specific load requirements. |

| Various Contact Pad Sizes & Surfaces | Use pads with different shapes or materials to protect product surfaces or improve grip. |

| Articulating Pads | Pads that can adjust angle or position to match load geometry for full contact. |

| Quick-Disconnect Mounting | Enables faster removal or swapping of the attachment. |

| Frame Bumper / Protection | Added protection on the clamp frame to guard against impacts or abrasive loads. |

| Tilt Control | Ability to tilt or angle the clamp slightly for better load engagement. |

| Load Cushion | Cushioned contact to reduce impact and protect delicate cartons. |

| Independent Arm Control | Each arm can move independently for precise positioning in tight or asymmetric loads. |

| Regenerative Valve | Improves arm speed on trucks with limited hydraulic flow by recovering hydraulic energy. |

| External Sideshift | Allows the entire clamp body to shift sideways for easier load alignment. |

| Alternate Valve Configurations | Options for left-hand or right-hand third / fourth function hydraulic setups. |

| Application-Specific Customization | Tailored design changes to match industry or product needs. |

Whether it’s about forklifts, parts, or services, we’ve got you covered. Our team is ready to help you find the right solution. Just let us know what you need.

1511 Railroad Street Corona, CA 92880

sales@scielifts.com

Phone : (951) 735-2905

By submitting this form, you agree to receive marketing emails from SCIE Lifts. You can unsubscribe at any time using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact