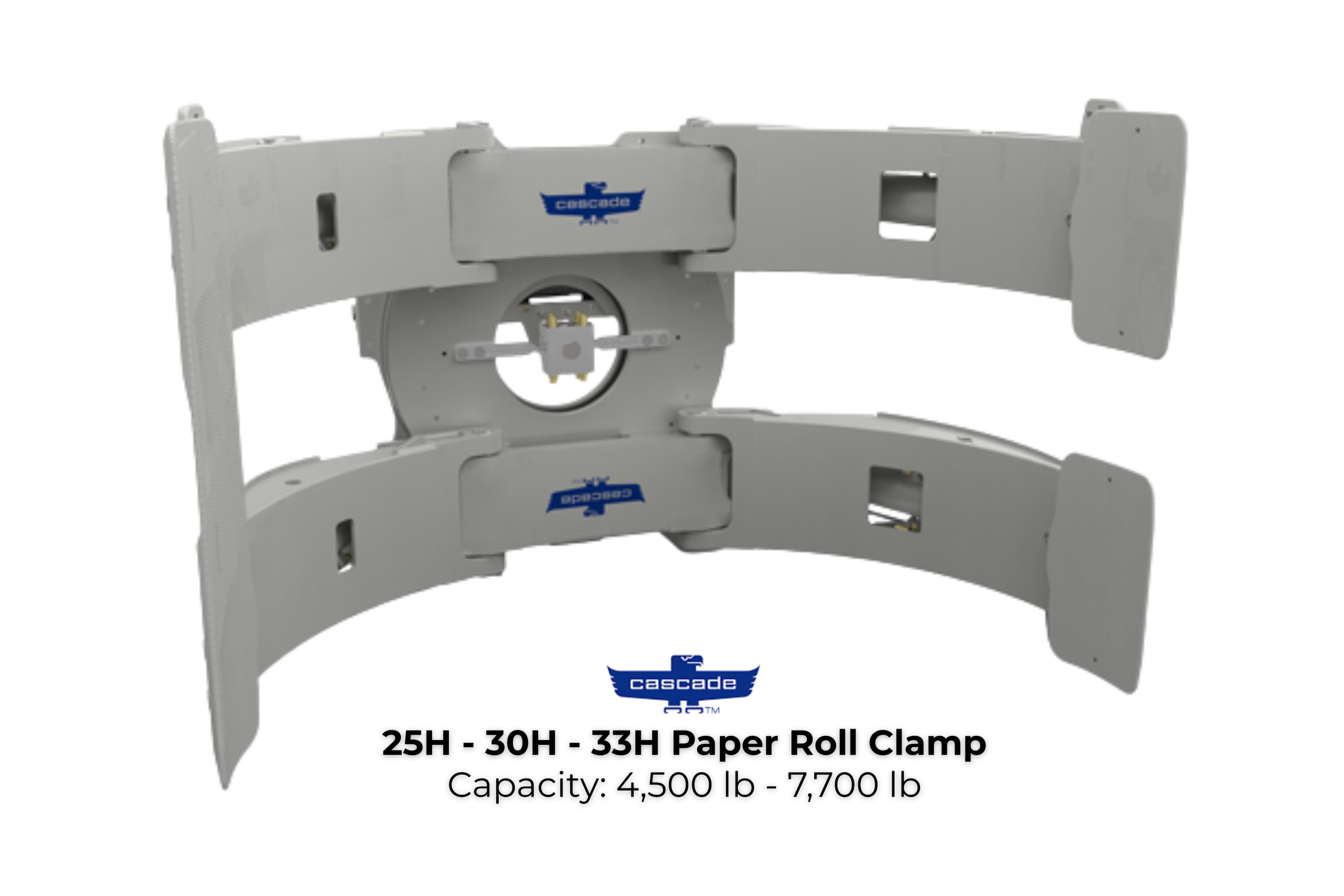

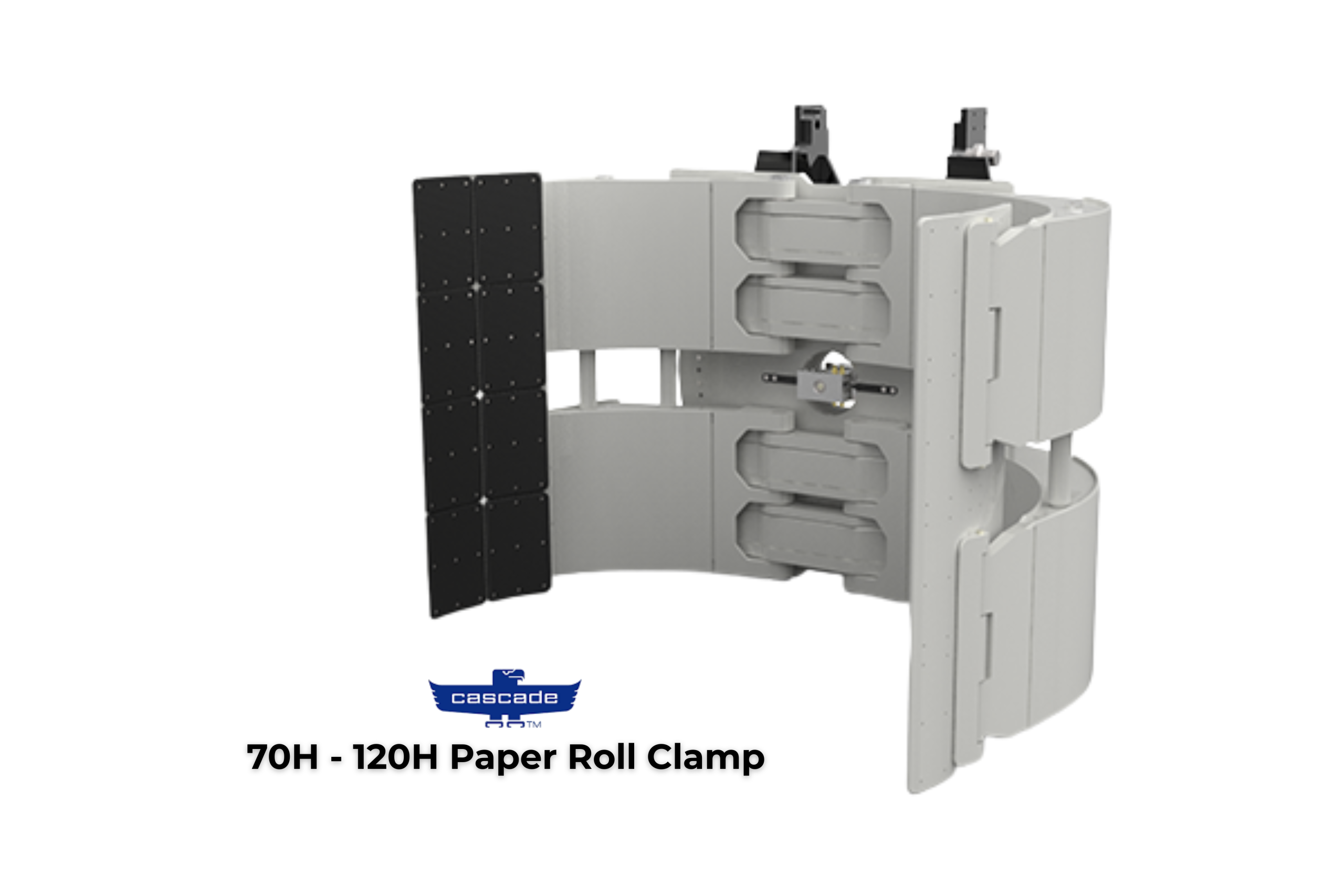

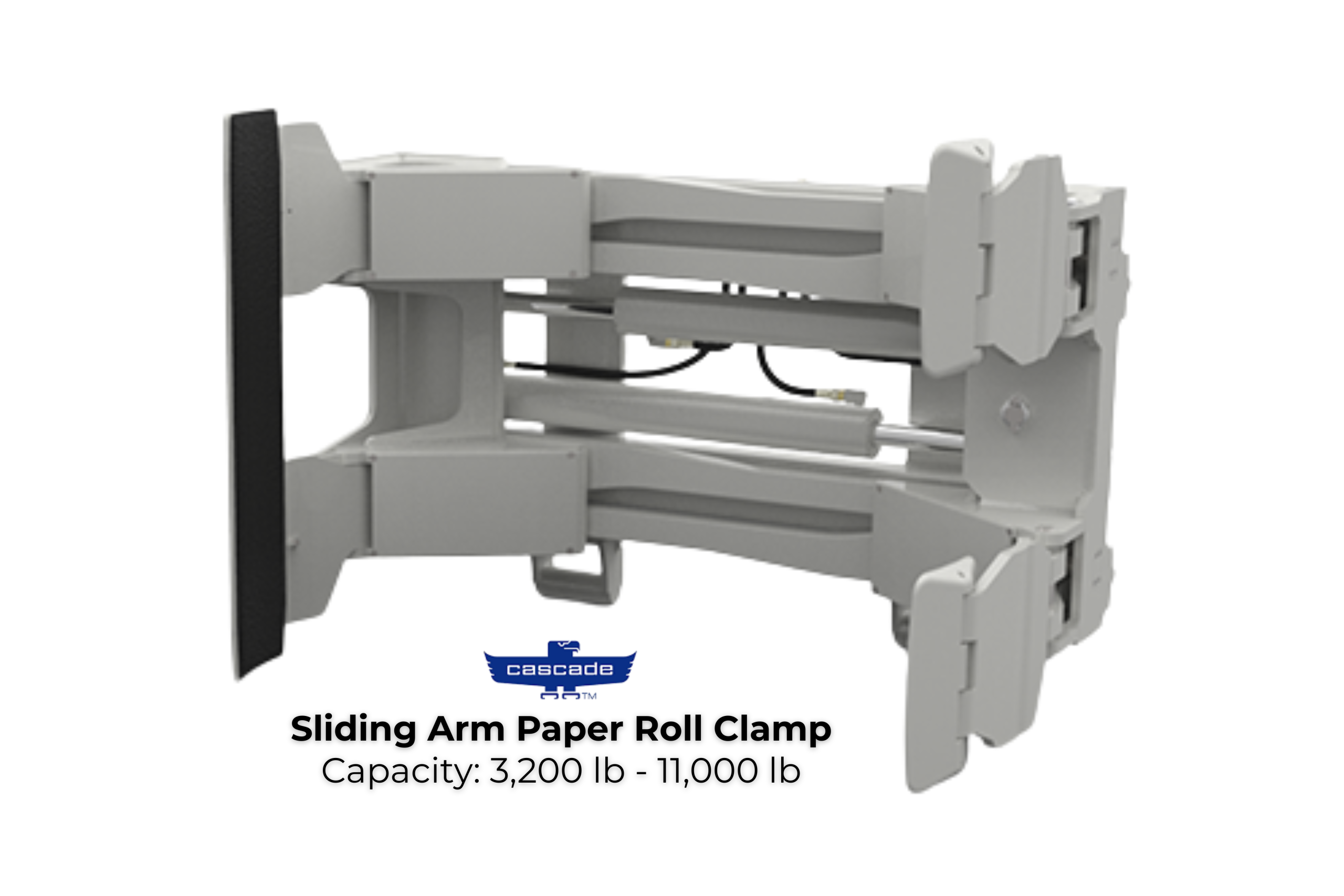

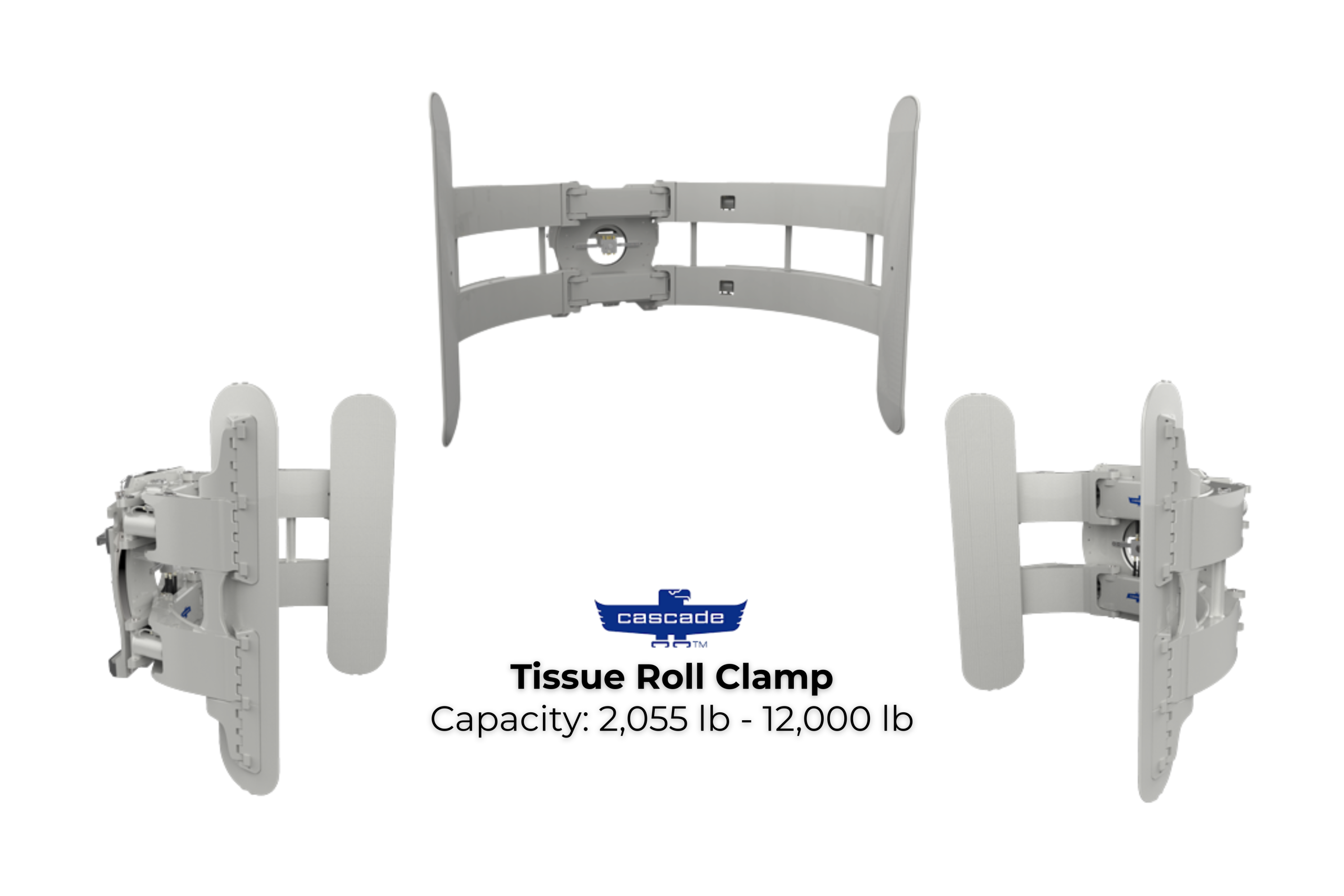

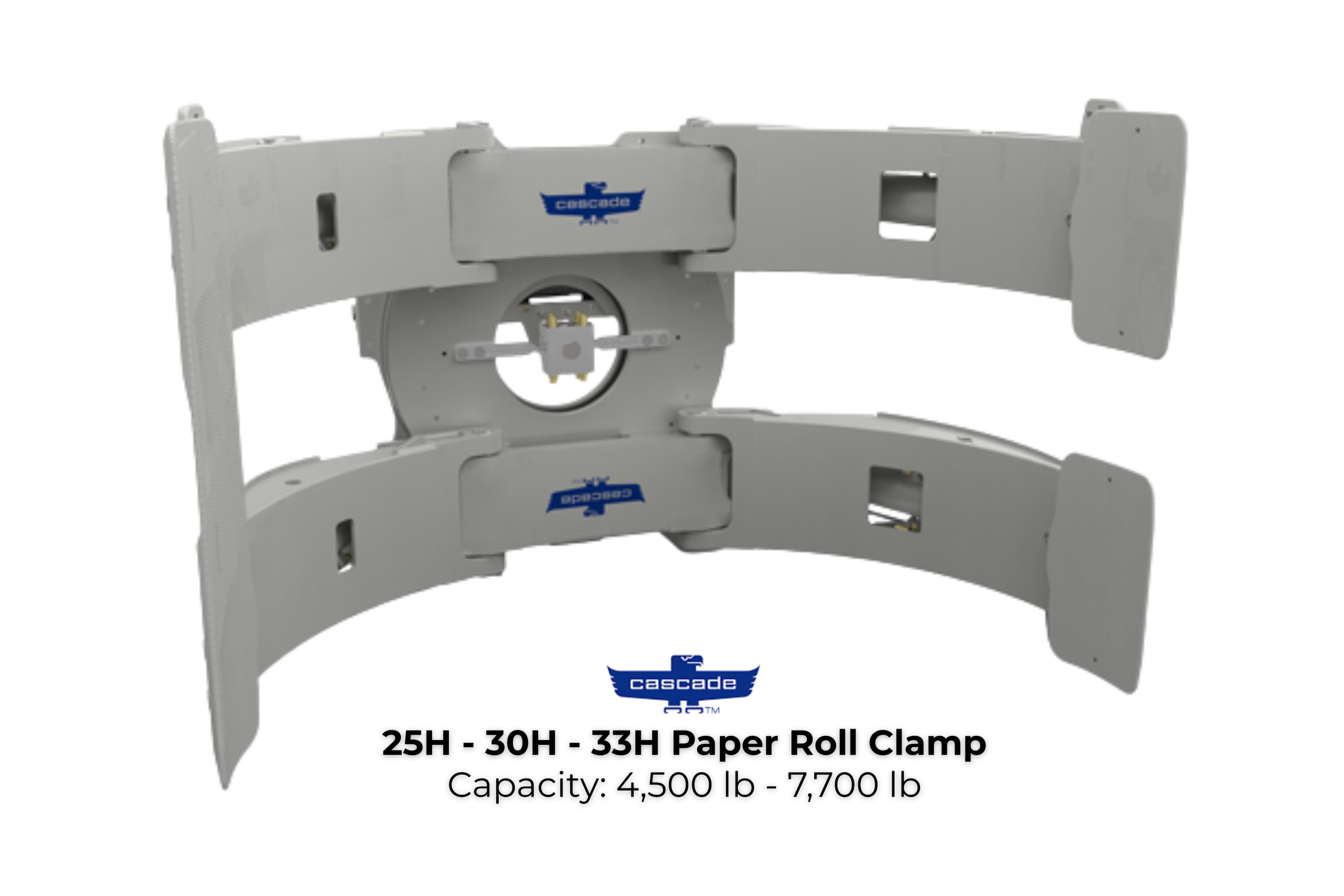

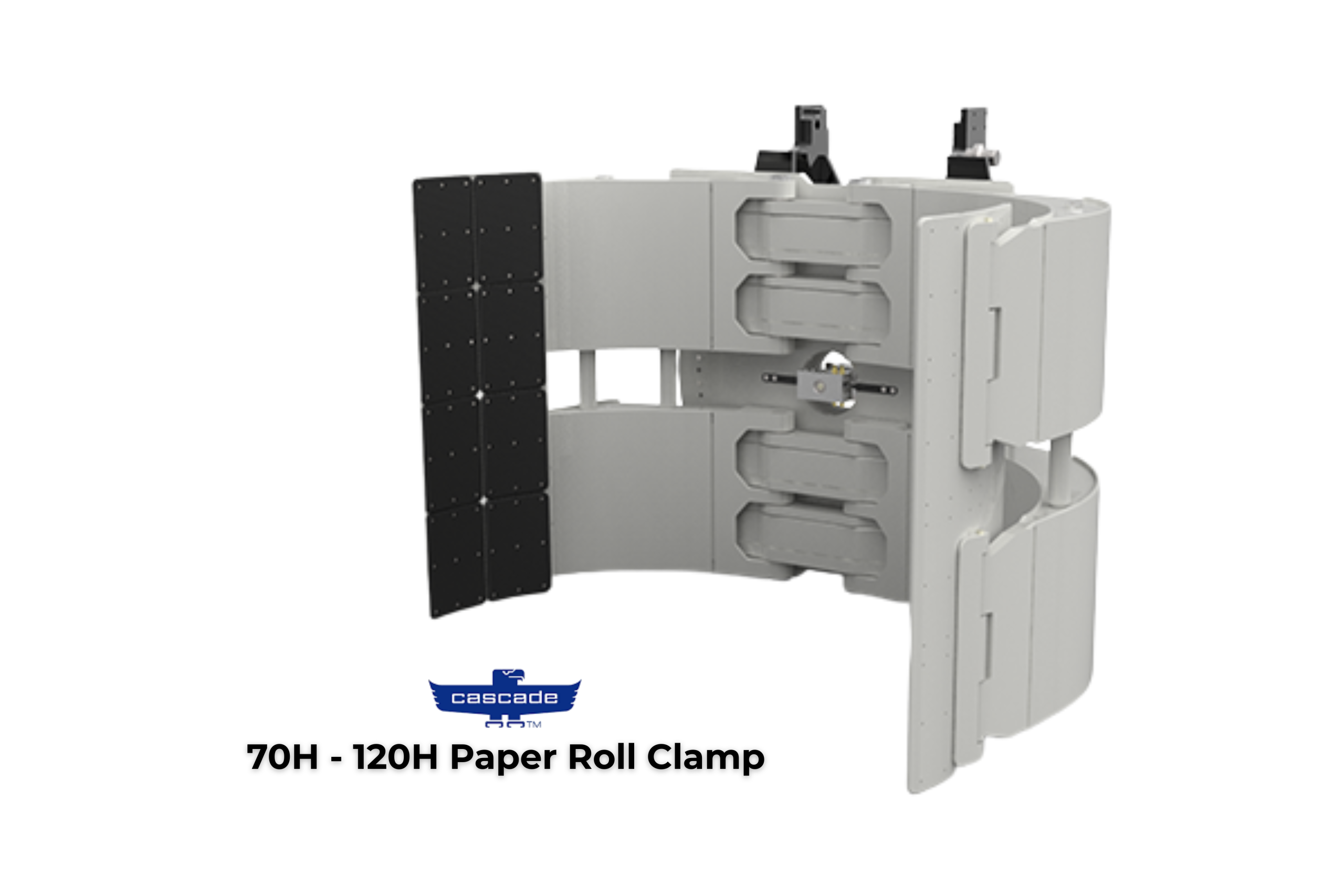

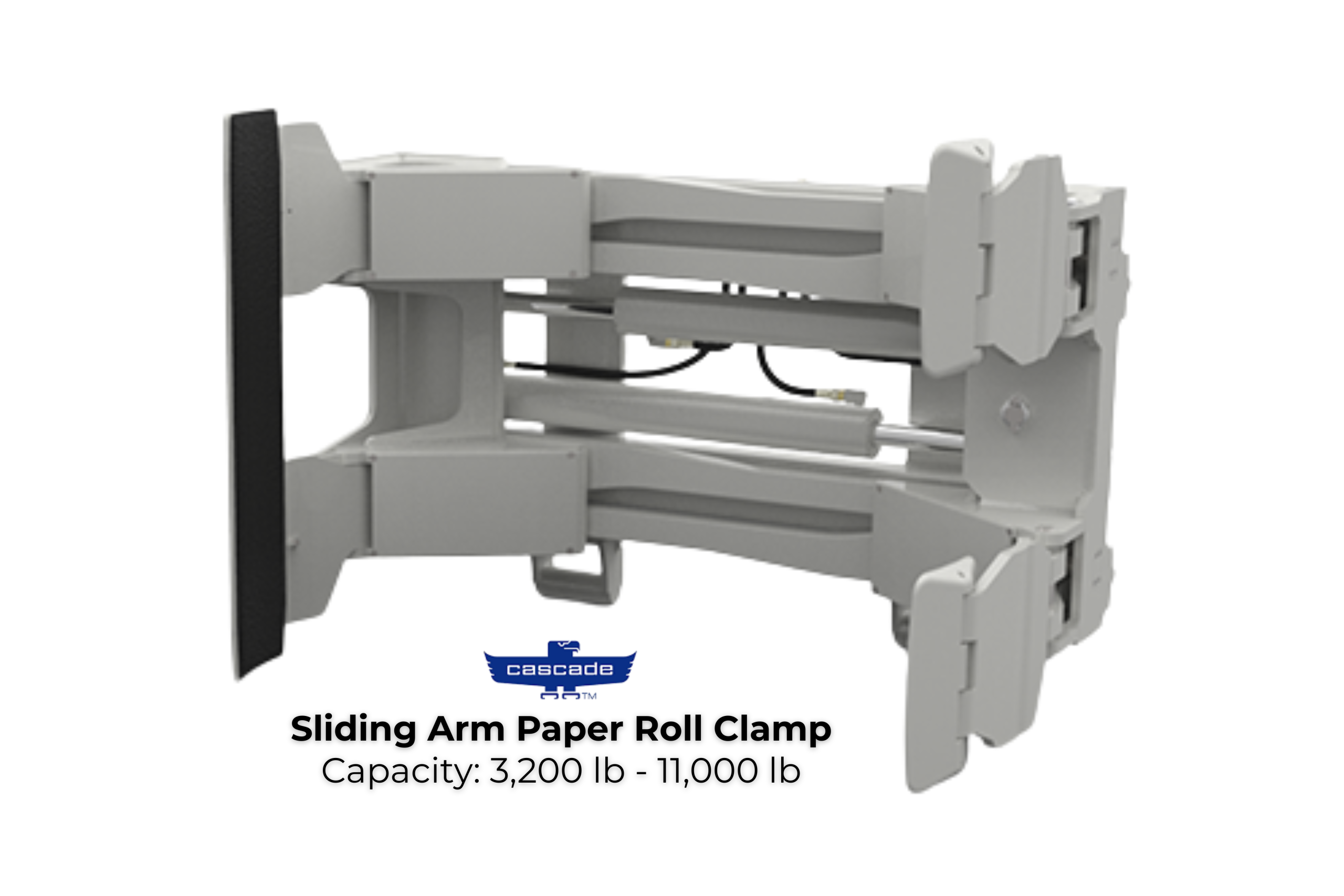

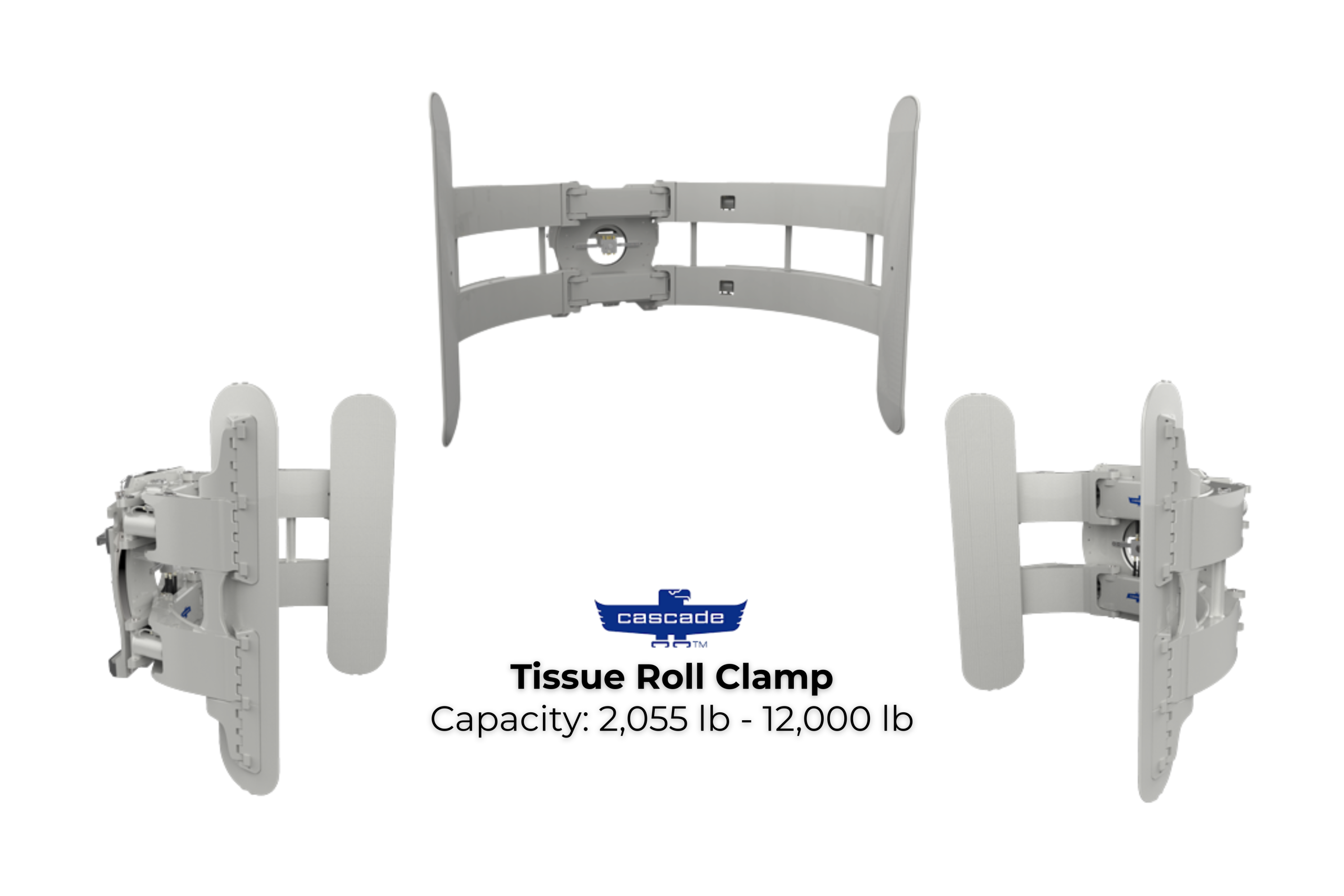

Cascade paper roll clamps are engineered to handle paper rolls regardless of diameter, weight or type of paper. From lightweight, compact options, to rugged and reliable clamps for demanding operations, these paper roll clamps can handle paper rolls of every size.

Designed to deliver perfect rolls, Cascade paper roll clamps offer a variety of damage reducing options including: tilt control, rotational control, multi-setting pressure relief valves, application specific contact pads and many other features.

Choose from a wide variety of options to ensure that each step in the process is precise, practiced and controlled. Deliver the perfect roll, every time.

| Product Features | Description |

|---|---|

| Ultra-Thin Pad Profile | Enables the clamp to “knife” between tightly stacked rolls without damaging surfaces. |

| Pad Alignment System (Dual Spring Technology) | Keeps clamp pads properly aligned, improving contact and reducing slippage or misalignment. |

| Pad Protectors / Guarding | Protects pad edges and prolongs pad life in heavy-duty or abrasive conditions. |

| Robust Rotator / High Torque Drive | Ensures strong, continuous rotation (often 360°) to orient rolls as needed. |

| Excellent Visibility Through Arms / Frame | Provides the operator with better line of sight to reduce handling damage. |

| Arm Styles & Variations (Solid, Split, Sliding, Pivot, Swing Frame) | Adapts to different roll geometries, multiple roll handling, tight spaces, or special layouts. |

| Fast Arm Speed / Optimized Hydraulics | Reduces cycle times in high-throughput operations. |

| Durability & Structural Strength | Heavy-duty arm construction, robust frames, and sealed components withstand continuous use. |

| Rotation Options (360° or 180° Stop Groups) | Some models allow you to limit rotation or use full continuous rotation depending on application needs. |

| Multiple Pad / Multi-Roll Handling | Certain clamps can support 2, 3, or 4 pad configurations or handle multiple rolls simultaneously. |

| Model / Series | Capacity / Roll Range | Key Dimensions & Weights | Hydraulic / Performance Specs |

|---|---|---|---|

| 77F Series | 6,250 lb @ 72″ roll | Effective Thickness ~ 8.6″ (Class III) | Min / Rec / Max Flow: 10 / 15 / 20 GPM; Max Pressure: 2,300 psi |

| 120F / 150F | For large, heavy rolls (kraft, linerboard, coated paper) | — | Continuous 360° rotation, heavy-duty rotator drivetrain |

| 45F | Mid-size roll handling | — | Rotator speed: 5.0 RPM @ 57 L/min; torque ~ 8,150 Nm @ 140 bar |

| 34H / 38H / 42H (H-Series mid-to-high capacity) | 6,250 – 9,920 lb roll capacity | Attachment weight 2,850 – 4,500 lb | Supports Class III – IV mounting; roll range 8 – 85 in (varies by model) |

| 20H / 18H Series | 3,750 lb @ 30″ load | Effective thickness ~ 8.4″; HCG ~13.6″ ; Horizontal COG ~11.7″ | Roll range: 8″ to 60″; continuous 360° rotation |

| 90F | 9,000 lb @ 30″ load | Effective Thickness ~ 7.8″; Horizontal COG ~12.2″ | Mounting Class: IV; Max flow 20 GPM; Max pressure 2,300 psi |

| Options | Description |

|---|---|

| Arm Style / Frame Type Options | Choose among fixed-frame, swing-frame, or positioned short-arm configurations, depending on needed maneuverability and roll ranges. |

| Split Arm / Independent Arm Operation | Arms may be split so each side can move independently, useful when handling rolls of different diameters on each side. |

| Short Arm Positioning / Variable Arm Lengths | The short arm can be adjustable or repositionable to optimize for smaller rolls or mixed ranges. |

| Pad Types / Contact Pad Options | Different pad materials or profiles (e.g. “ultra thin” pad profiles for tight spaces) to protect roll surfaces. |

| Pad Protectors / Guards | Protects pad edges and prolongs pad life under abrasive or high-use conditions. |

| Rotation Options | 360° continuous rotation or 180° stop options, depending on application requirements. |

| Multi-Pad / Multi-Roll Handling | Configurations supporting 2, 3, or 4 pad setups for handling multiple rolls simultaneously. |

| High-Flow Revolving Connection | A high-flow swivel joint to support fast arm speed, especially useful for electric or high-cycle trucks. |

| Visibility Enhancements | Designs that improve operator sight lines through arms or frame for safe, precise handling. |

| Customized Mounting / Class Options | Ability to match different mounting classes (e.g. III, IV) and adapt to your forklift’s carriage system. |

Cascade paper roll clamps are engineered to handle paper rolls regardless of diameter, weight or type of paper. From lightweight, compact options, to rugged and reliable clamps for demanding operations, these paper roll clamps can handle paper rolls of every size.

Designed to deliver perfect rolls, Cascade paper roll clamps offer a variety of damage reducing options including: tilt control, rotational control, multi-setting pressure relief valves, application specific contact pads and many other features.

Choose from a wide variety of options to ensure that each step in the process is precise, practiced and controlled. Deliver the perfect roll, every time.

| Product Features | Description |

|---|---|

| Ultra-Thin Pad Profile | Enables the clamp to “knife” between tightly stacked rolls without damaging surfaces. |

| Pad Alignment System (Dual Spring Technology) | Keeps clamp pads properly aligned, improving contact and reducing slippage or misalignment. |

| Pad Protectors / Guarding | Protects pad edges and prolongs pad life in heavy-duty or abrasive conditions. |

| Robust Rotator / High Torque Drive | Ensures strong, continuous rotation (often 360°) to orient rolls as needed. |

| Excellent Visibility Through Arms / Frame | Provides the operator with better line of sight to reduce handling damage. |

| Arm Styles & Variations (Solid, Split, Sliding, Pivot, Swing Frame) | Adapts to different roll geometries, multiple roll handling, tight spaces, or special layouts. |

| Fast Arm Speed / Optimized Hydraulics | Reduces cycle times in high-throughput operations. |

| Durability & Structural Strength | Heavy-duty arm construction, robust frames, and sealed components withstand continuous use. |

| Rotation Options (360° or 180° Stop Groups) | Some models allow you to limit rotation or use full continuous rotation depending on application needs. |

| Multiple Pad / Multi-Roll Handling | Certain clamps can support 2, 3, or 4 pad configurations or handle multiple rolls simultaneously. |

| Model / Series | Capacity / Roll Range | Key Dimensions & Weights | Hydraulic / Performance Specs |

|---|---|---|---|

| 77F Series | 6,250 lb @ 72″ roll | Effective Thickness ~ 8.6″ (Class III) | Min / Rec / Max Flow: 10 / 15 / 20 GPM; Max Pressure: 2,300 psi |

| 120F / 150F | For large, heavy rolls (kraft, linerboard, coated paper) | — | Continuous 360° rotation, heavy-duty rotator drivetrain |

| 45F | Mid-size roll handling | — | Rotator speed: 5.0 RPM @ 57 L/min; torque ~ 8,150 Nm @ 140 bar |

| 34H / 38H / 42H (H-Series mid-to-high capacity) | 6,250 – 9,920 lb roll capacity | Attachment weight 2,850 – 4,500 lb | Supports Class III – IV mounting; roll range 8 – 85 in (varies by model) |

| 20H / 18H Series | 3,750 lb @ 30″ load | Effective thickness ~ 8.4″; HCG ~13.6″ ; Horizontal COG ~11.7″ | Roll range: 8″ to 60″; continuous 360° rotation |

| 90F | 9,000 lb @ 30″ load | Effective Thickness ~ 7.8″; Horizontal COG ~12.2″ | Mounting Class: IV; Max flow 20 GPM; Max pressure 2,300 psi |

| Options | Description |

|---|---|

| Arm Style / Frame Type Options | Choose among fixed-frame, swing-frame, or positioned short-arm configurations, depending on needed maneuverability and roll ranges. |

| Split Arm / Independent Arm Operation | Arms may be split so each side can move independently, useful when handling rolls of different diameters on each side. |

| Short Arm Positioning / Variable Arm Lengths | The short arm can be adjustable or repositionable to optimize for smaller rolls or mixed ranges. |

| Pad Types / Contact Pad Options | Different pad materials or profiles (e.g. “ultra thin” pad profiles for tight spaces) to protect roll surfaces. |

| Pad Protectors / Guards | Protects pad edges and prolongs pad life under abrasive or high-use conditions. |

| Rotation Options | 360° continuous rotation or 180° stop options, depending on application requirements. |

| Multi-Pad / Multi-Roll Handling | Configurations supporting 2, 3, or 4 pad setups for handling multiple rolls simultaneously. |

| High-Flow Revolving Connection | A high-flow swivel joint to support fast arm speed, especially useful for electric or high-cycle trucks. |

| Visibility Enhancements | Designs that improve operator sight lines through arms or frame for safe, precise handling. |

| Customized Mounting / Class Options | Ability to match different mounting classes (e.g. III, IV) and adapt to your forklift’s carriage system. |

Whether it’s about forklifts, parts, or services, we’ve got you covered. Our team is ready to help you find the right solution. Just let us know what you need.

1511 Railroad Street Corona, CA 92880

sales@scielifts.com

Phone : (951) 735-2905