The Noblelift PTE45N (The Edge 45) is a compact and powerful electric pallet truck with a 4,500 lb capacity and a 48 V brushless DC drive motor. It offers smooth, quiet, and reliable performance with suspension stability casters for safer handling on uneven floors. Its ergonomic design, maintenance-free lithium battery, and tight turning radius make it ideal for elevators, trailers, containers, and narrow warehouse spaces.

| Product Features | Description |

|---|---|

| Smart Lithium Battery | Maintenance-free 48V / 20Ah lithium-ion battery allows fast and opportunity charging between shifts. The integrated BMS (Battery Management System) monitors temperature, voltage, and performance for safe and efficient operation. |

| Quick Battery Exchange | Smart slide-out design enables one-hand battery removal or replacement within seconds — no tools required. |

| Easy Maintenance | All major components are easily accessible without special tools. The sealed hydraulic system eliminates hoses and reduces leak risks, improving long-term reliability. |

| Robust Steel Frame | Surrounded by stamped steel and a reinforced apron to protect internal components. Full-length double-sided C-shape fork reinforcements ensure frame rigidity and durability. |

| Excellent Climbing Ability | Handles grades up to 7% when loaded and 16% when unloaded. Equipped with a German INTORQ electromagnetic brake for added control and safety. |

| Ergonomic Smart Tiller | Soft-grip handle and oversized buttons ensure comfortable control — even while wearing gloves. |

| Integrated PIN Panel Display | LCD panel shows battery status, hour meter, and on-board diagnostics with error codes. PIN access allows authorized operation only. |

| Turtle Speed Mode | Enables operation with the tiller in an upright position — perfect for maneuvering in tight spaces such as trailers, containers, and elevators. |

| Responsive Travel Controls | Dual butterfly-style thumb controls for forward/reverse travel, plus horn, emergency reverse switch, and electric lift/lower buttons. |

| Advanced Curtis CAN-Bus System | CAN-bus architecture simplifies diagnostics, improves communication between components, and minimizes downtime. |

| Parameter | Description |

|---|---|

| Load Capacity / Load Center | 4,500 lb @ 24" |

| Power / Battery | 48 V / 20 Ah lithium-ion (maintenance-free, integrated BMS system) |

| Charger | 48 V / 9 A external charger, 110 VAC |

| Fork Dimensions (Standard) | 27" W × 45.3" L |

| Alternate Fork Size (Option) | 21" W × 45" L (model variant) |

| Fork Height — Lowered / Raised | 3.1" (lowered) / 7.6" (max) |

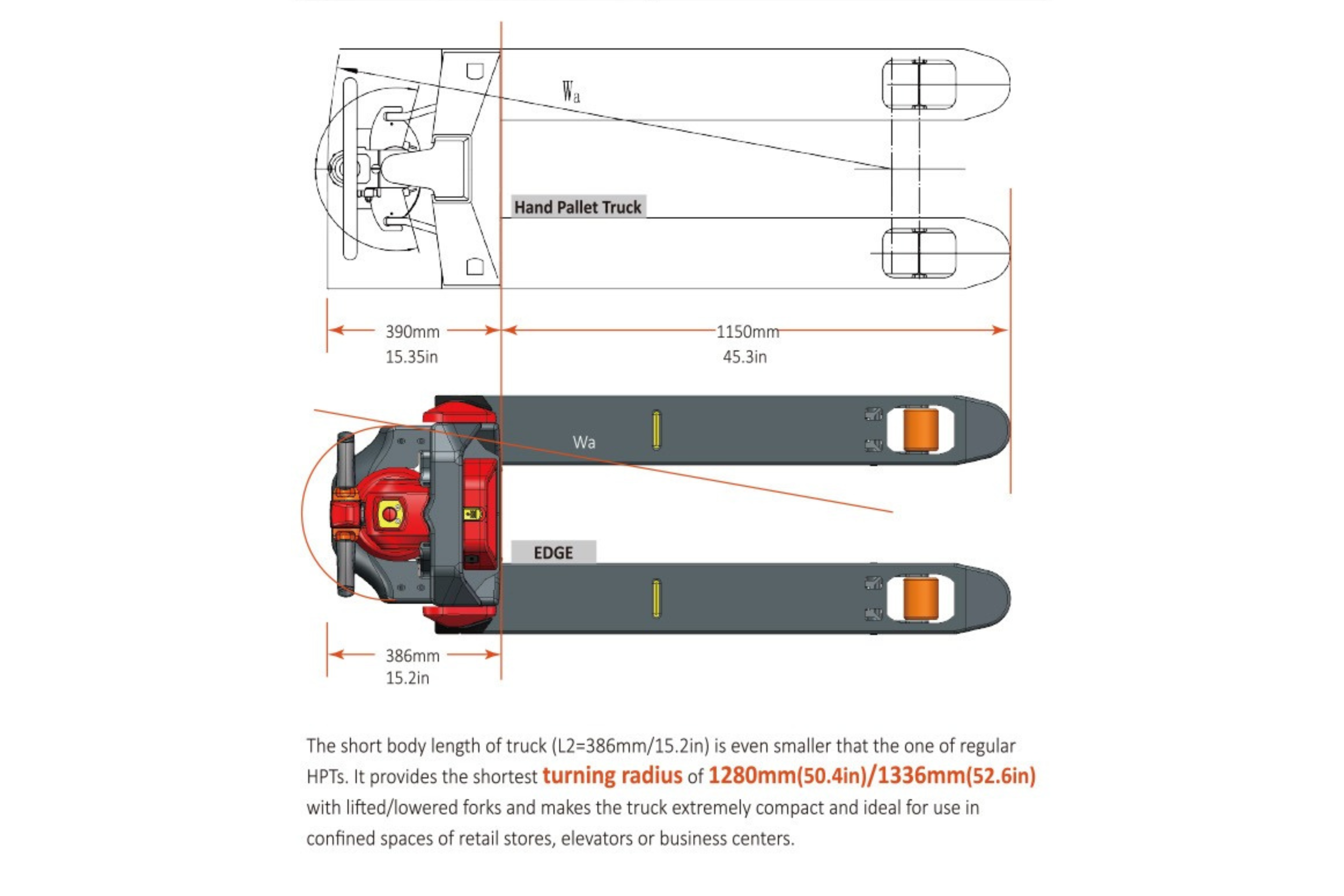

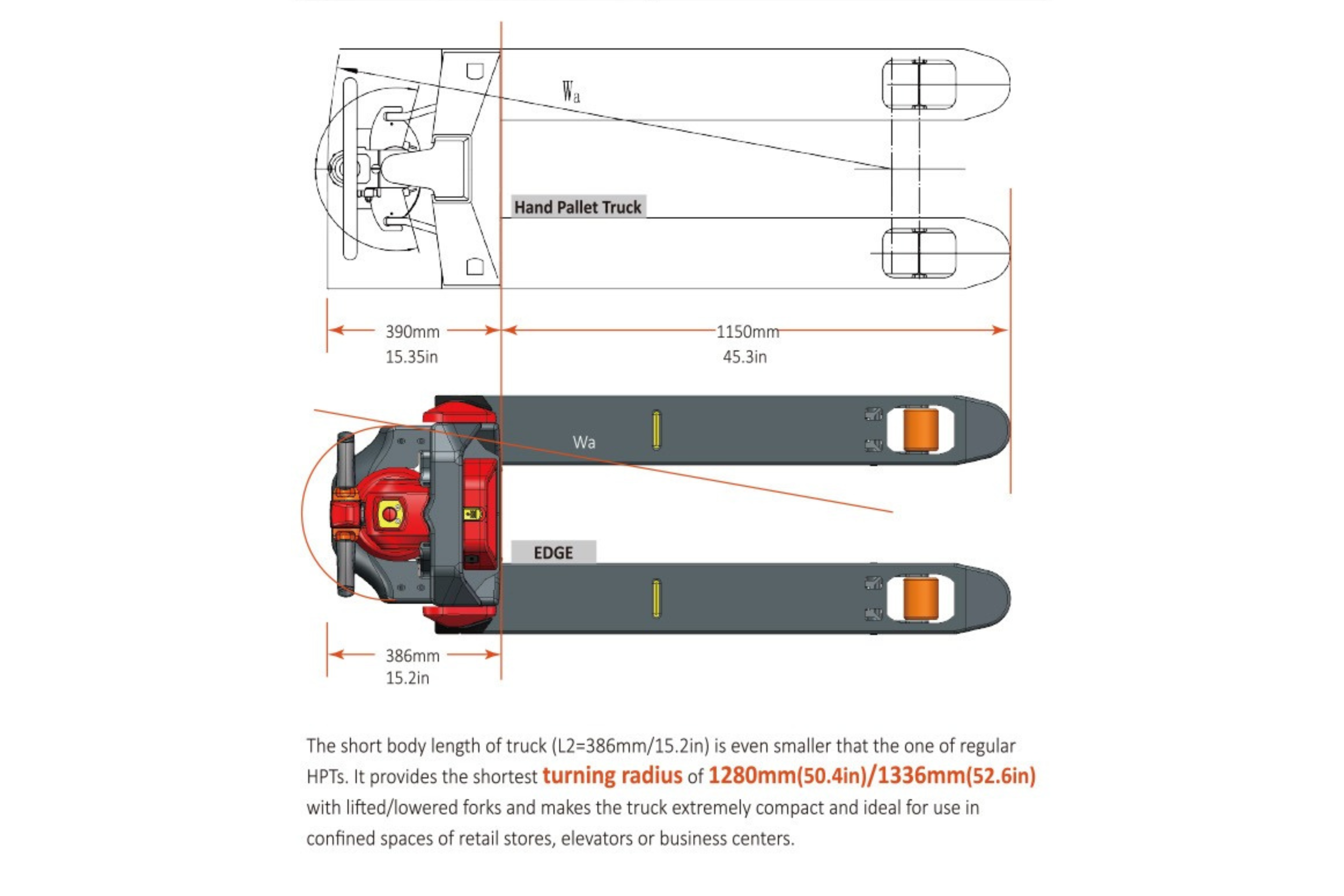

| Turning Radius (Forks Lifted / Lowered) | 50.4" / 52.6" |

| Travel Speed — Laden / Unladen | ≈ 3.0 mph (loaded) / 3.2 mph (empty) |

| Gradeability — Laden / Unladen | 7% / 16% |

| Drive / Load Wheels | Drive: 8.3" × 2.8" (polyurethane); Load: 3.1" × 3.7" (polyurethane) |

| Controller | Curtis CAN-bus controller |

| Approx. Service Weight | ~330 lb |

| Options | Description |

|---|---|

| Alternate Fork Configurations | Available in narrower or extended fork sizes depending on pallet requirements — such as 21″ W × 45″ L or 27″ W × 45.3″ L standard. Ideal for warehouses handling mixed pallet types. |

| Additional Lithium Battery Pack | Option to include a second 48 V / 20 Ah lithium battery for extended runtime. Quick swap design lets you replace packs between shifts for continuous operation. |

| Extra Battery Charger | Optional second charger supports multi-shift operations or parallel charging of spare batteries. Plug-and-play design using standard 110 VAC outlet. |

| Traction & Load Wheel Options | Available with upgraded polyurethane or non-marking drive and load wheels for improved traction or floor protection in specialized environments. |

| Load Backrest Options | Optional operator/pallet backrests available in 42″, 48″, or 60″ heights. Provides added safety and stability when transporting taller or stacked loads. |

| Custom Color / Finish | Units can be customized in special color finishes for brand alignment or facility requirements (available upon request). |

The Noblelift PTE45N (The Edge 45) is a compact and powerful electric pallet truck with a 4,500 lb capacity and a 48 V brushless DC drive motor. It offers smooth, quiet, and reliable performance with suspension stability casters for safer handling on uneven floors. Its ergonomic design, maintenance-free lithium battery, and tight turning radius make it ideal for elevators, trailers, containers, and narrow warehouse spaces.

| Product Features | Description |

|---|---|

| Smart Lithium Battery | Maintenance-free 48V / 20Ah lithium-ion battery allows fast and opportunity charging between shifts. The integrated BMS (Battery Management System) monitors temperature, voltage, and performance for safe and efficient operation. |

| Quick Battery Exchange | Smart slide-out design enables one-hand battery removal or replacement within seconds — no tools required. |

| Easy Maintenance | All major components are easily accessible without special tools. The sealed hydraulic system eliminates hoses and reduces leak risks, improving long-term reliability. |

| Robust Steel Frame | Surrounded by stamped steel and a reinforced apron to protect internal components. Full-length double-sided C-shape fork reinforcements ensure frame rigidity and durability. |

| Excellent Climbing Ability | Handles grades up to 7% when loaded and 16% when unloaded. Equipped with a German INTORQ electromagnetic brake for added control and safety. |

| Ergonomic Smart Tiller | Soft-grip handle and oversized buttons ensure comfortable control — even while wearing gloves. |

| Integrated PIN Panel Display | LCD panel shows battery status, hour meter, and on-board diagnostics with error codes. PIN access allows authorized operation only. |

| Turtle Speed Mode | Enables operation with the tiller in an upright position — perfect for maneuvering in tight spaces such as trailers, containers, and elevators. |

| Responsive Travel Controls | Dual butterfly-style thumb controls for forward/reverse travel, plus horn, emergency reverse switch, and electric lift/lower buttons. |

| Advanced Curtis CAN-Bus System | CAN-bus architecture simplifies diagnostics, improves communication between components, and minimizes downtime. |

| Parameter | Description |

|---|---|

| Load Capacity / Load Center | 4,500 lb @ 24" |

| Power / Battery | 48 V / 20 Ah lithium-ion (maintenance-free, integrated BMS system) |

| Charger | 48 V / 9 A external charger, 110 VAC |

| Fork Dimensions (Standard) | 27" W × 45.3" L |

| Alternate Fork Size (Option) | 21" W × 45" L (model variant) |

| Fork Height — Lowered / Raised | 3.1" (lowered) / 7.6" (max) |

| Turning Radius (Forks Lifted / Lowered) | 50.4" / 52.6" |

| Travel Speed — Laden / Unladen | ≈ 3.0 mph (loaded) / 3.2 mph (empty) |

| Gradeability — Laden / Unladen | 7% / 16% |

| Drive / Load Wheels | Drive: 8.3" × 2.8" (polyurethane); Load: 3.1" × 3.7" (polyurethane) |

| Controller | Curtis CAN-bus controller |

| Approx. Service Weight | ~330 lb |

| Options | Description |

|---|---|

| Alternate Fork Configurations | Available in narrower or extended fork sizes depending on pallet requirements — such as 21″ W × 45″ L or 27″ W × 45.3″ L standard. Ideal for warehouses handling mixed pallet types. |

| Additional Lithium Battery Pack | Option to include a second 48 V / 20 Ah lithium battery for extended runtime. Quick swap design lets you replace packs between shifts for continuous operation. |

| Extra Battery Charger | Optional second charger supports multi-shift operations or parallel charging of spare batteries. Plug-and-play design using standard 110 VAC outlet. |

| Traction & Load Wheel Options | Available with upgraded polyurethane or non-marking drive and load wheels for improved traction or floor protection in specialized environments. |

| Load Backrest Options | Optional operator/pallet backrests available in 42″, 48″, or 60″ heights. Provides added safety and stability when transporting taller or stacked loads. |

| Custom Color / Finish | Units can be customized in special color finishes for brand alignment or facility requirements (available upon request). |

Whether it’s about forklifts, parts, or services, we’ve got you covered. Our team is ready to help you find the right solution. Just let us know what you need.

1511 Railroad Street Corona, CA 92880

sales@scielifts.com

Phone : (951) 735-2905