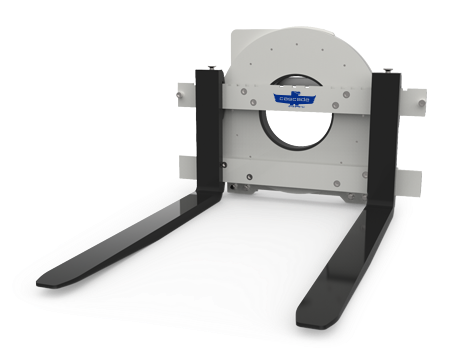

Cascade paper roll clamps are engineered to handle paper rolls regardless of diameter, weight or type of paper. From lightweight, compact options, to rugged and reliable clamps for demanding operations, these paper roll clamps can handle paper rolls of every size.

Designed to deliver perfect rolls, Cascade paper roll clamps offer a variety of damage reducing options including: tilt control, rotational control, multi-setting pressure relief valves, application specific contact pads and many other features.

Choose from a wide variety of options to ensure that each step in the process is precise, practiced and controlled. Deliver the perfect roll, every time.

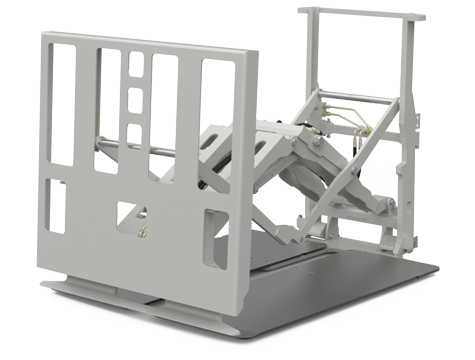

Damage Reducing Solutions:

- Manual 3-position pressure regulator – basic method for controlling the amount of pressure applied to the paper roll.

- Hydraulic Force Control (HFC) – automatic clamp force system that changes the clamp force proportional to the load weight by continuously sensing the hydraulic pressure necessary to lift the load.

- Adaptive Force Control (AFC) – computer controlled system that prevents the driver from over-clamping the load by controlling the clamp force.

- Load cushion – Hoist System Accumulator that absorbs shocks and reduces the clamp force required to handle the load.

- Clamp open guard – provides an added level of security to prevent accidental dropping of load

- Electronic pressure regulator – allows operator to select proper clamp force with a control switch

- Wireless Pressure Monitor (WPM) – system to monitor the hydraulic pressure in the clamping cylinders on a real time basis.

Contact Pads:

- Herringbone

- Ribbed herringbone

- RXH Bonded Non-Marking Black Rubber

- Carbonless

- Bolt-on urethane domed profile

- Bolt-on rubber & urethane

- Tissue, single diameter

- Tissue, double diameter

- Tissue, convex